Counter-flow heat exchangers

95%

Efficiency

95%

Efficiency

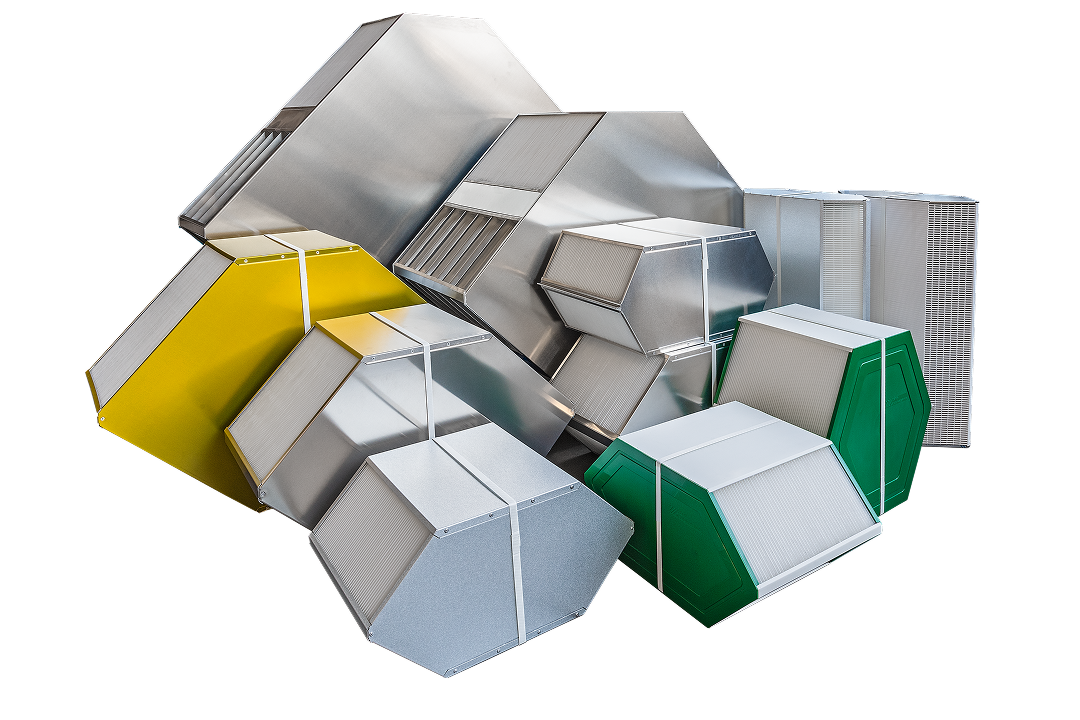

Product categories

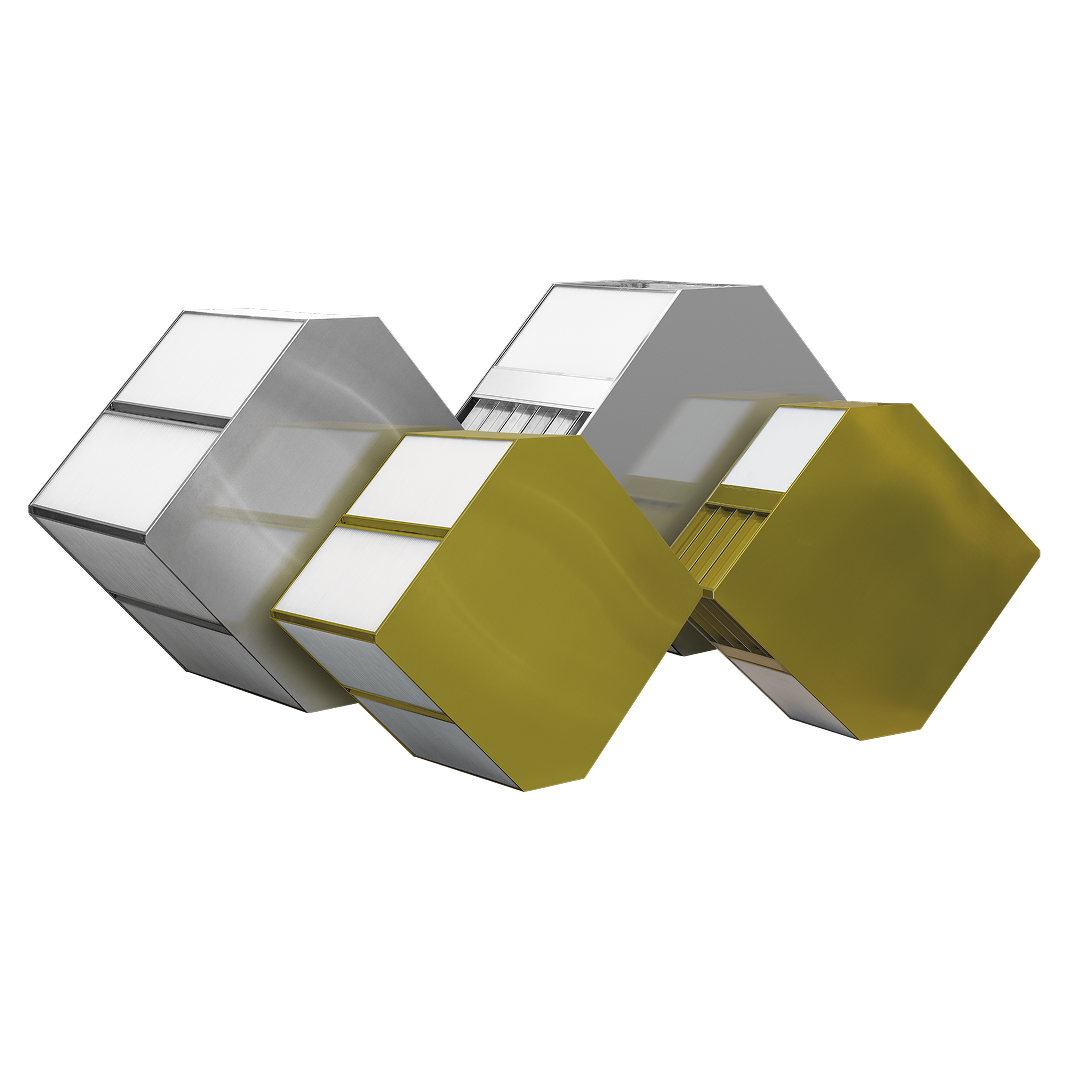

Sensible counter-flow heat exchangers

Series:

HU / HS / HC / HD-EX6

Thermoformed polystyrene cores for high heat recovery with low pressure drop. Monolithic, fully sealed structure prevents cross-contamination and is suitable for low- to medium-pressure systems.

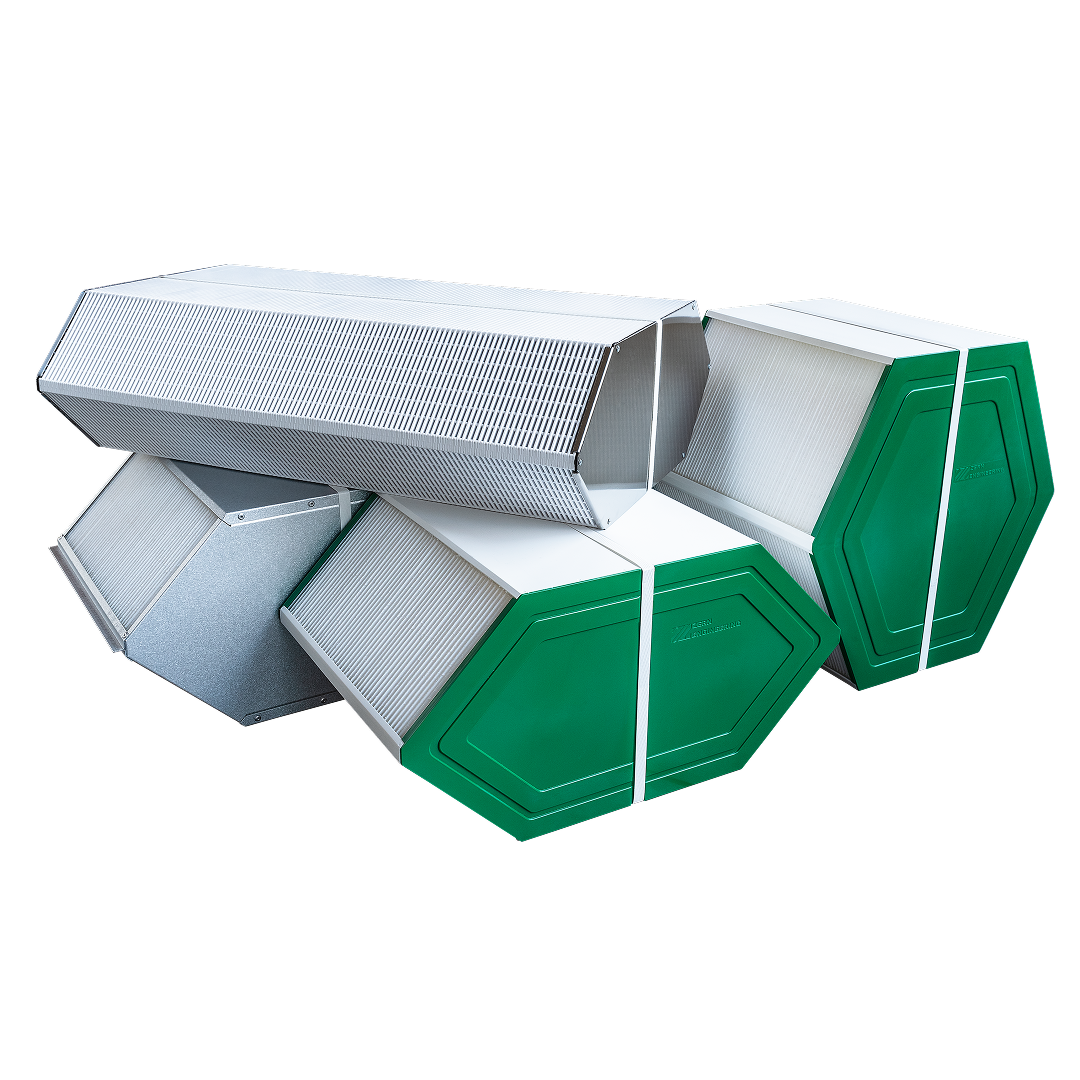

Enthalpy counter-flow heat exchangers

Series:

ECD / EC-EX6

Polymer plates bonded with a microporous, vapor-permeable membrane recover both heat and moisture - ideal for cold or dry climates and RH control.

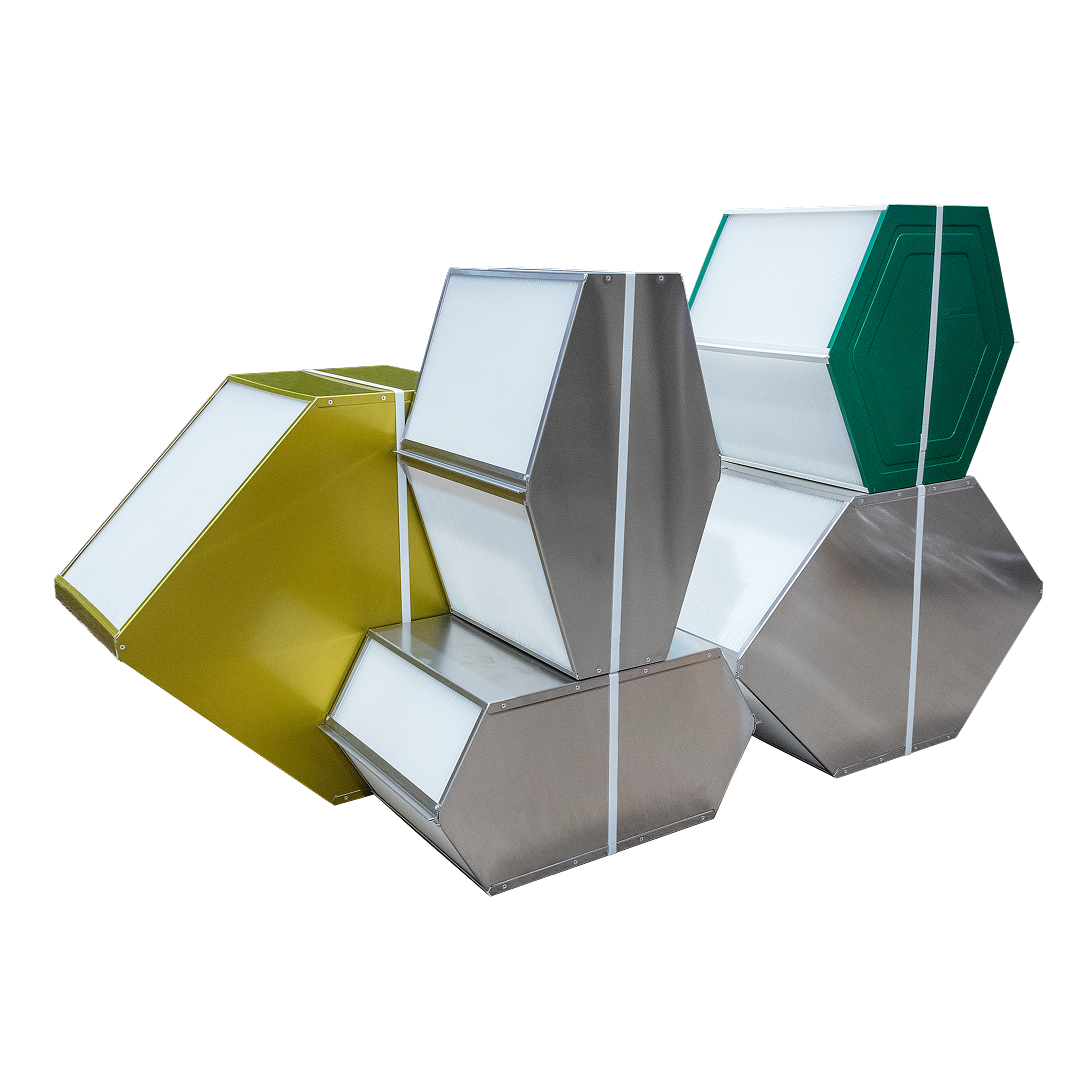

Combi counter-flow heat exchangers

Series:

Combi HU/HC-EX6

Twin-core modules joined by common plenums to handle higher airflows with a lower pressure drop while keeping all counter-flow benefits.

Technical features

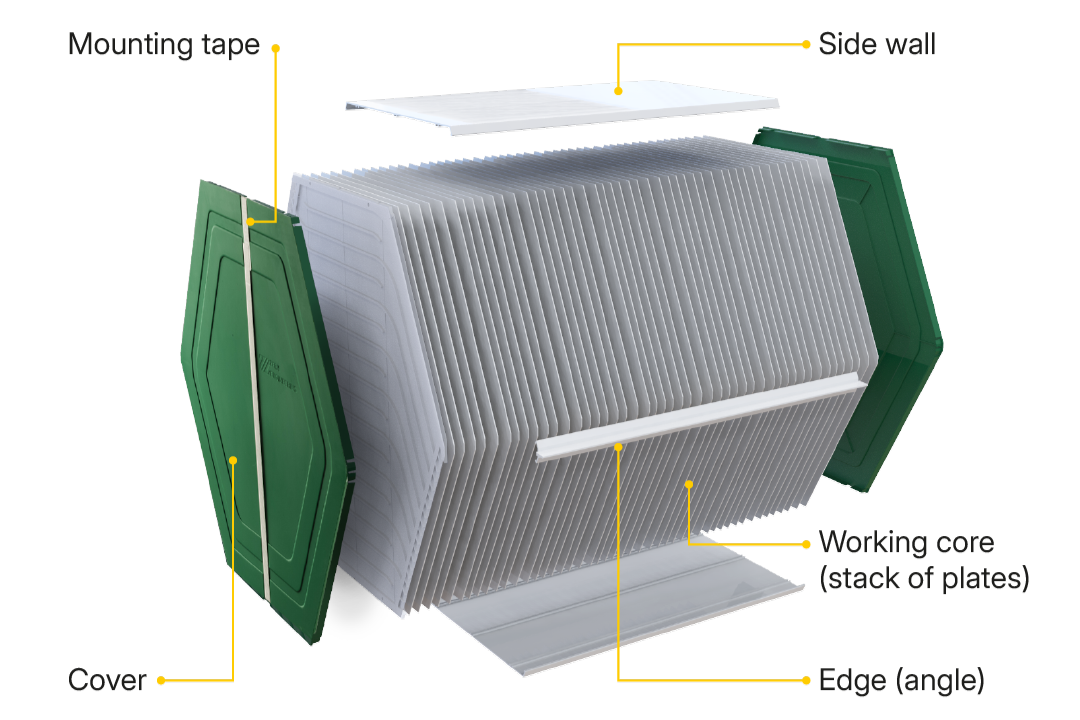

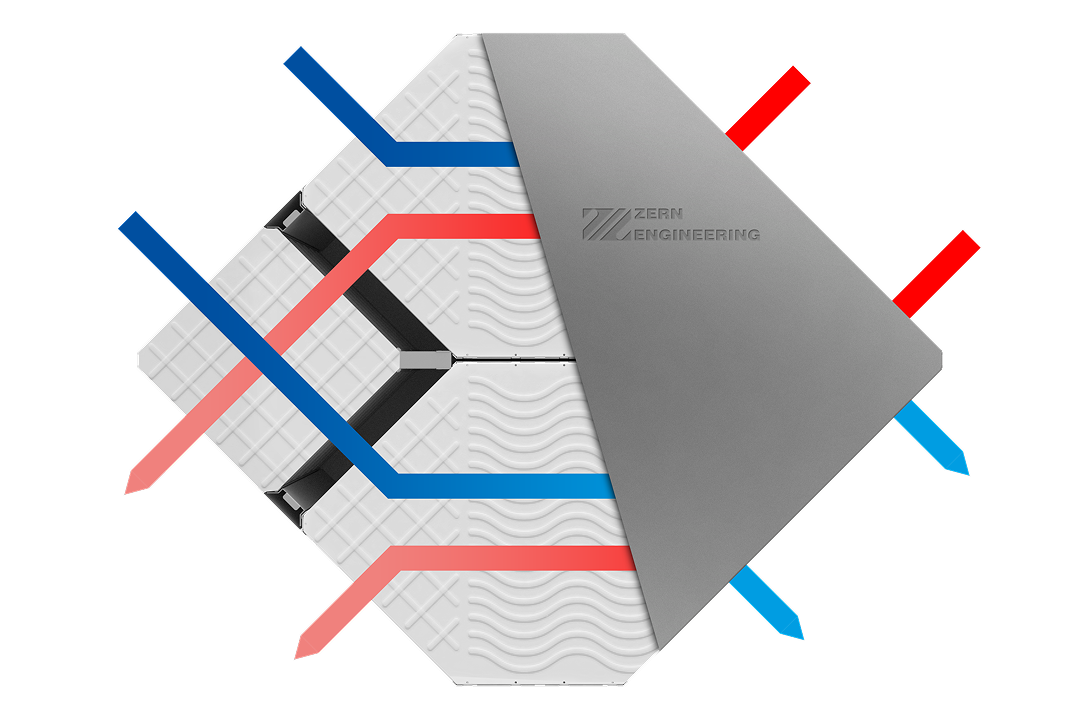

In counter-flow heat exchangers, two air streams flow in opposite directions through thin channels formed by a layered polystyrene or polymer membrane structure. This counter-flow configuration ensures a consistently high temperature gradient across the entire core length, enabling highly efficient heat transfer.

Thermoformed polystyrene plates or polymer-based enthalpy plates arranged in a tightly packed structure. The design provides:

Product catalog

Discover ZERN ENGINEERING’s full range of heat exchangers. Our product catalog provides detailed specifications, material options, and performance data to help you select the optimal solution for any application