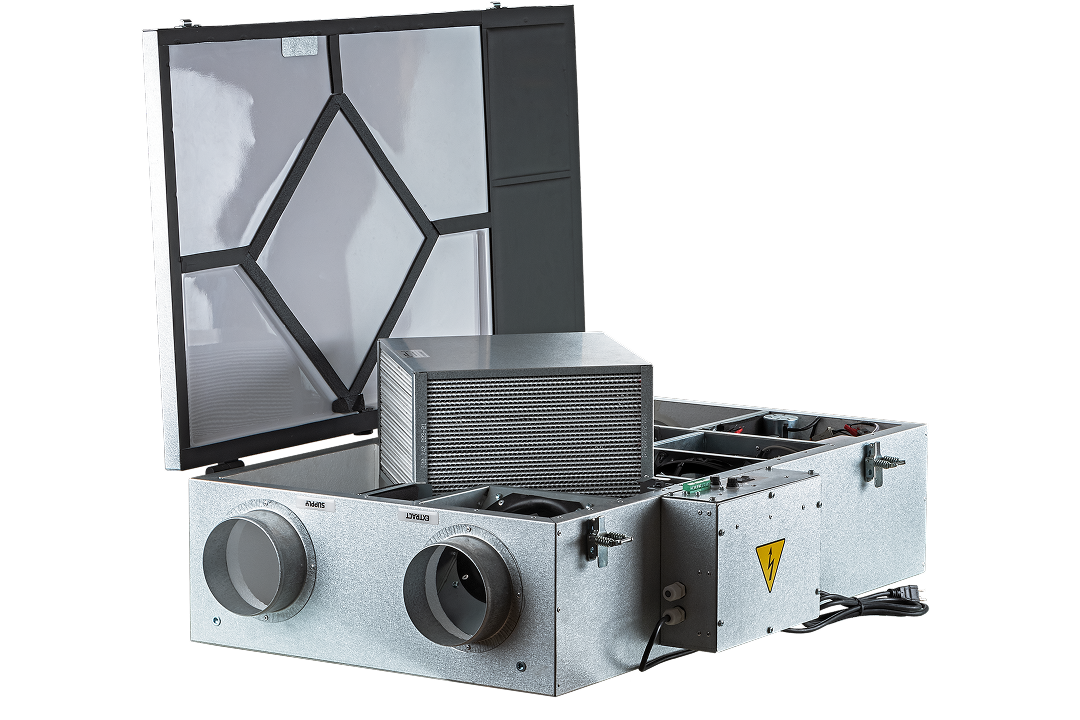

Cross-flow heat exchangers

75%

Efficiency

75%

Efficiency

Product categories

Sensible cross-flow heat exchangers

Series:

Hp-EX4

Polystyrene plates for applications requiring temperature-only recovery - dry zones, dehumidifiers, or sites needing absolute humidity separation.

Enthalpy cross-flow heat exchangers

Series:

E-EX4

Aluminum foil with vapor-permeable membrane for heat + moisture recovery - ideal for residential and light commercial comfort control.

Combi cross-flow heat exchangers

Series:

Combi Hp-EX4, Combi E-EX4

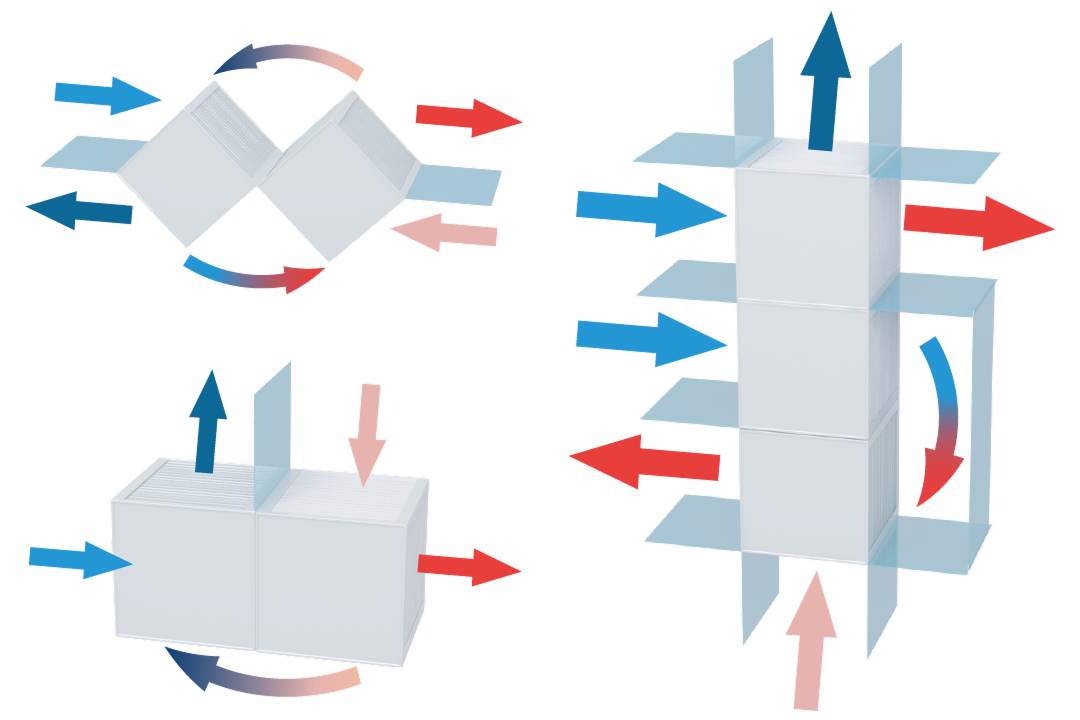

Multi-core assemblies that scale airflow for larger systems while keeping pressure drop low.

Key operational parameters

Technical features

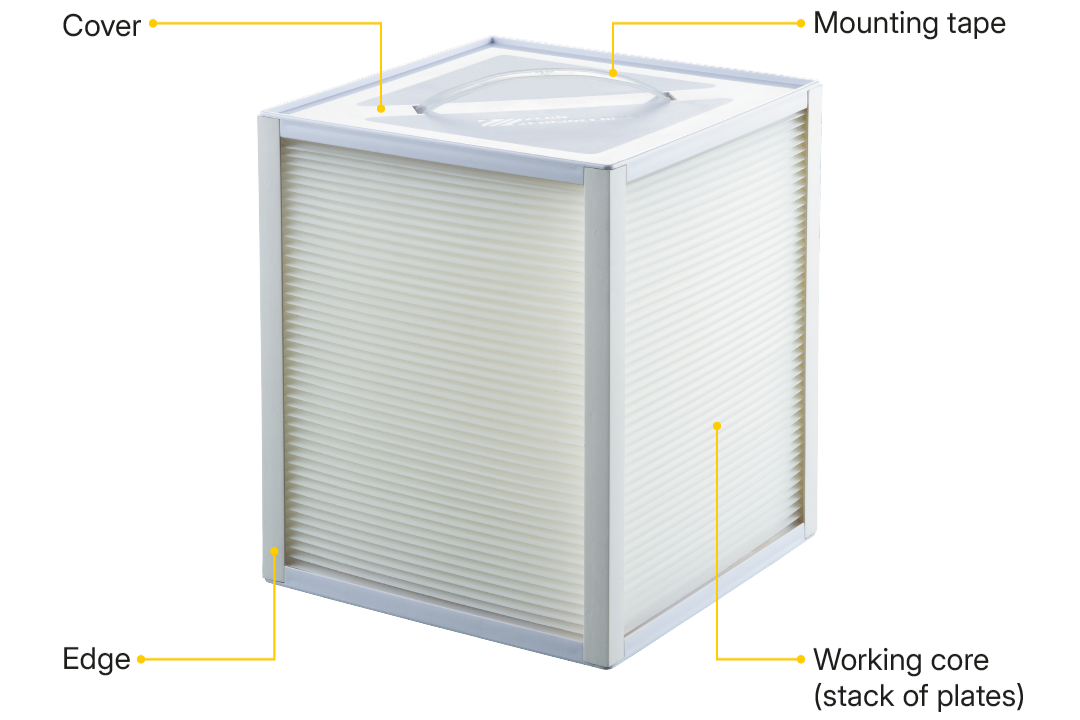

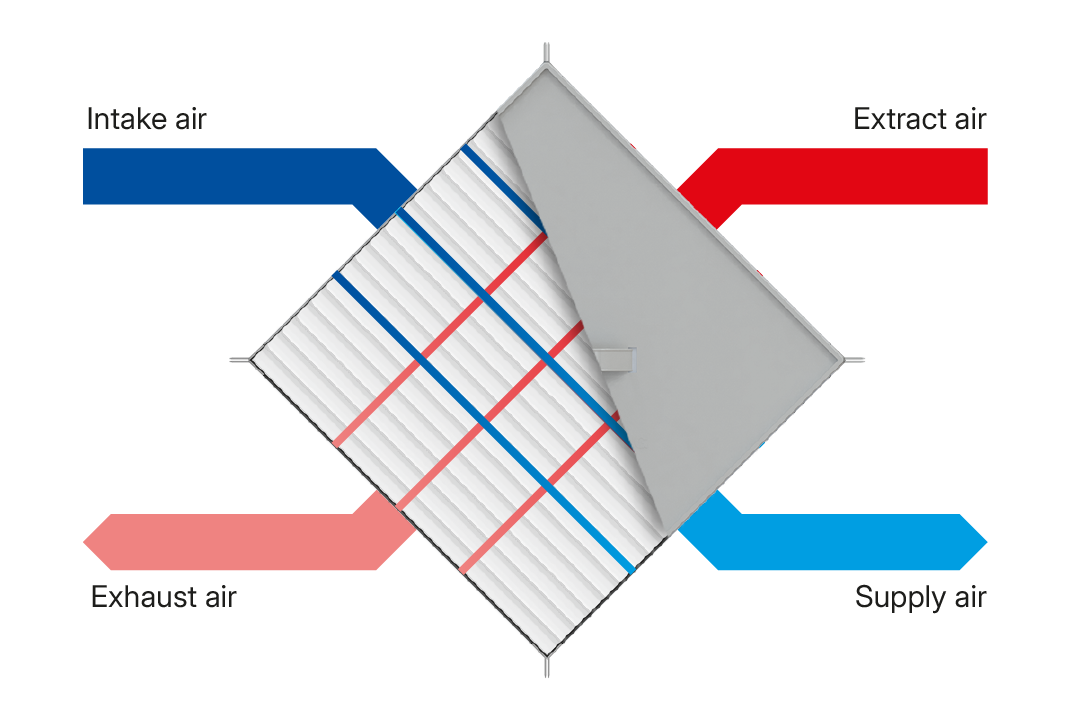

In cross-flow exchangers, supply and exhaust airstreams pass perpendicularly through separate thin channels formed by layered polystyrene plates or aluminum plates laminated with a vapor-permeable membrane. The 90° crossing maintains a strong local temperature, and with membrane cores, moisture, gradient across the plate walls while keeping the streams fully separated—delivering efficient energy recovery in a compact, low-profile core.

Stacked cross-flow cores use either thermoformed polystyrene plates (sensible) or aluminum plates laminated with a microporous vapor-permeable membrane (enthalpy), forming fully isolated, tightly packed channels that provide high heat-transfer surface area with low airflow resistance; the materials are corrosion-free, hygienic, and washable, with the membrane variant enabling controlled moisture diffusion while blocking gases and contaminants.

Product catalog

Discover ZERN ENGINEERING’s full range of heat exchangers. Our product catalog provides detailed specifications, material options, and performance data to help you select the optimal solution for any application