Combi Hp-EX4, Combi E-EX4

Technical features

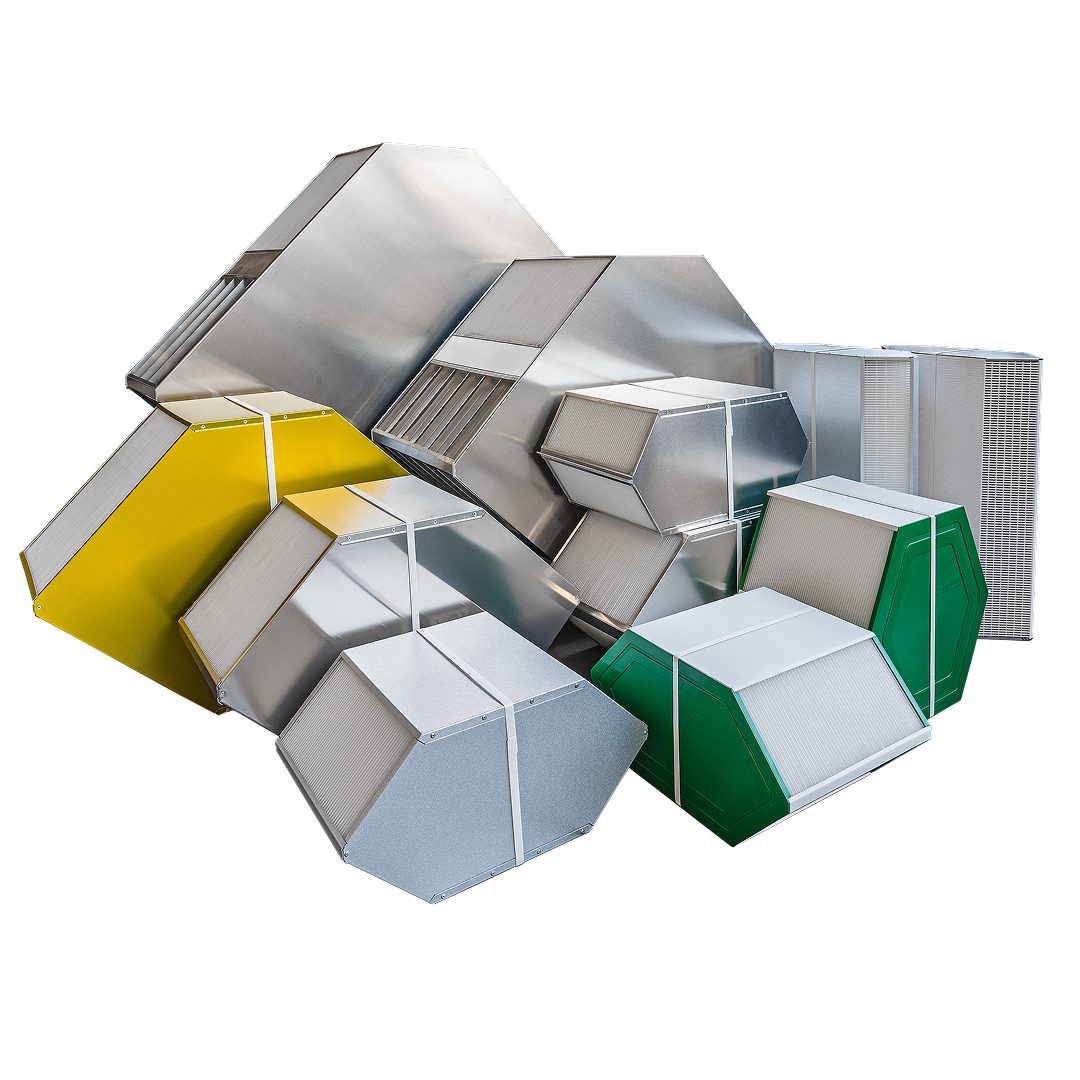

Design and structure

Supply and exhaust streams pass perpendicularly through channels formed by stacked plates or membrane-aluminum layers, transferring heat (and in enthalpy models, moisture) without mixing streams of air. What distinguishes the Combi design from a standard single-block model is the integration of several identical cross-flow cores operating in parallel within one casing. This modular format increases airflow capacity, maintains uniform performance, and keeps pressure drop low.

- Hp-EX4 (sensible): thermoformed polystyrene for heat-only recovery.

- E-EX4 (enthalpy): aluminum foil laminated with a vapor-permeable membrane for combined heat and moisture recovery.

- Aluzinc steel - economical and corrosion-resistant for long-lasting performance.

- Aluminum - lightweight, corrosion-resistant; good for humid sites.

- Stainless steel (AISI 304/316) - for aggressive/hygienic sites.

Main areas of use

Application

- Large commercial buildings - shopping centers, business complexes, offices, schools.

- Industrial facilities - production halls, warehouses, logistics centers.

- Hotel and wellness sector - hotels, sports and fitness centers, swimming pools.

- Public venues - airports, exhibition halls, arenas, transport hubs.

- Centralized HVAC systems - modular or custom AHUs requiring high-capacity energy recovery.

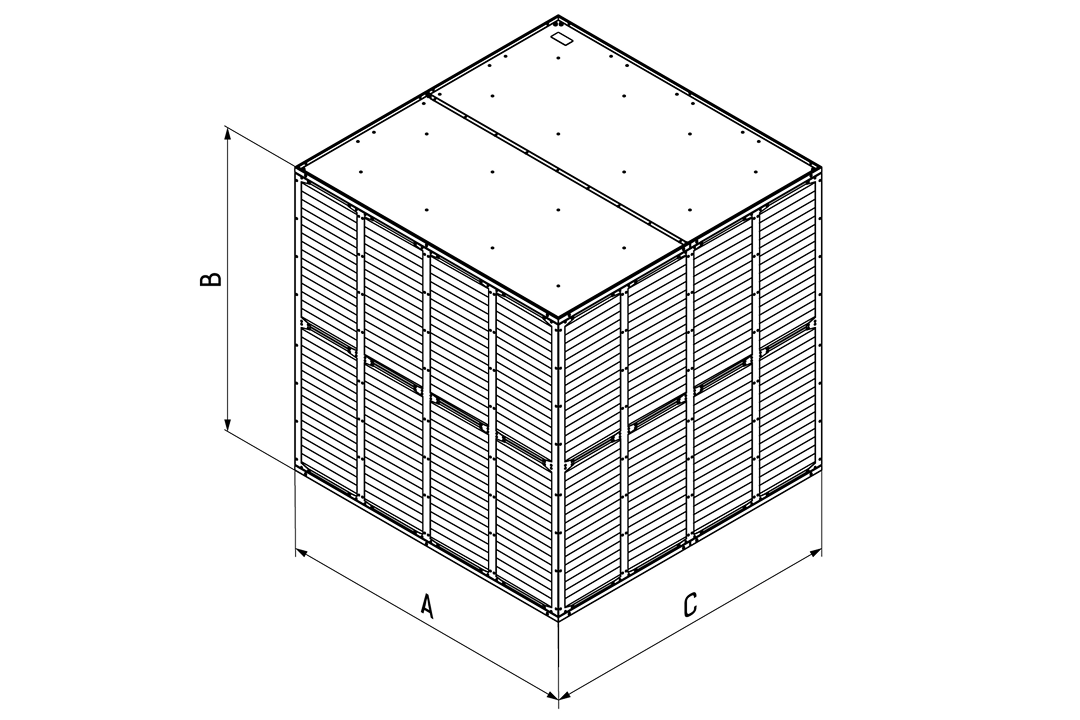

SIZES OF OUR HEAT EXCHANGERS

MODEL LINE

- Dimensions A and B are fixed. Dimension C is the width of the heat exchanger and can be varied.

- Each heat exchanger model can be manufactured with a depth (dimension C) ranging from 100 mm to 800 mm per unit.

- Heat exchangers with a width of 800 mm and above are supplied as two or more units.

| Series commercial group |

A width [mm] |

В height [mm] |

С depth [mm] |

h plate distance [mm] |

X casing modification |

| Combi Hp-EX4 | 400 - 3000 | 400 - 3000 | 100 - 3000 | 2.4 / 2.7 / 3 | 1 / 3 / 5 |

| Combi E-EX4 | 400 - 3000 | 400 - 3000 | 100 - 3000 | 2.7 / 4.5 | 1 / 3 / 5 |

Decoding Product Specifications

Designation key

Combi Hp/E-EX4

commercial group

A

width, length (mm)

C

depth (mm)

h

distance between plates (mm)

x

casing modification

- 1 - aluzinc

- 3 - aluminium

- 5 - stainless steel