R-EX

Technical features

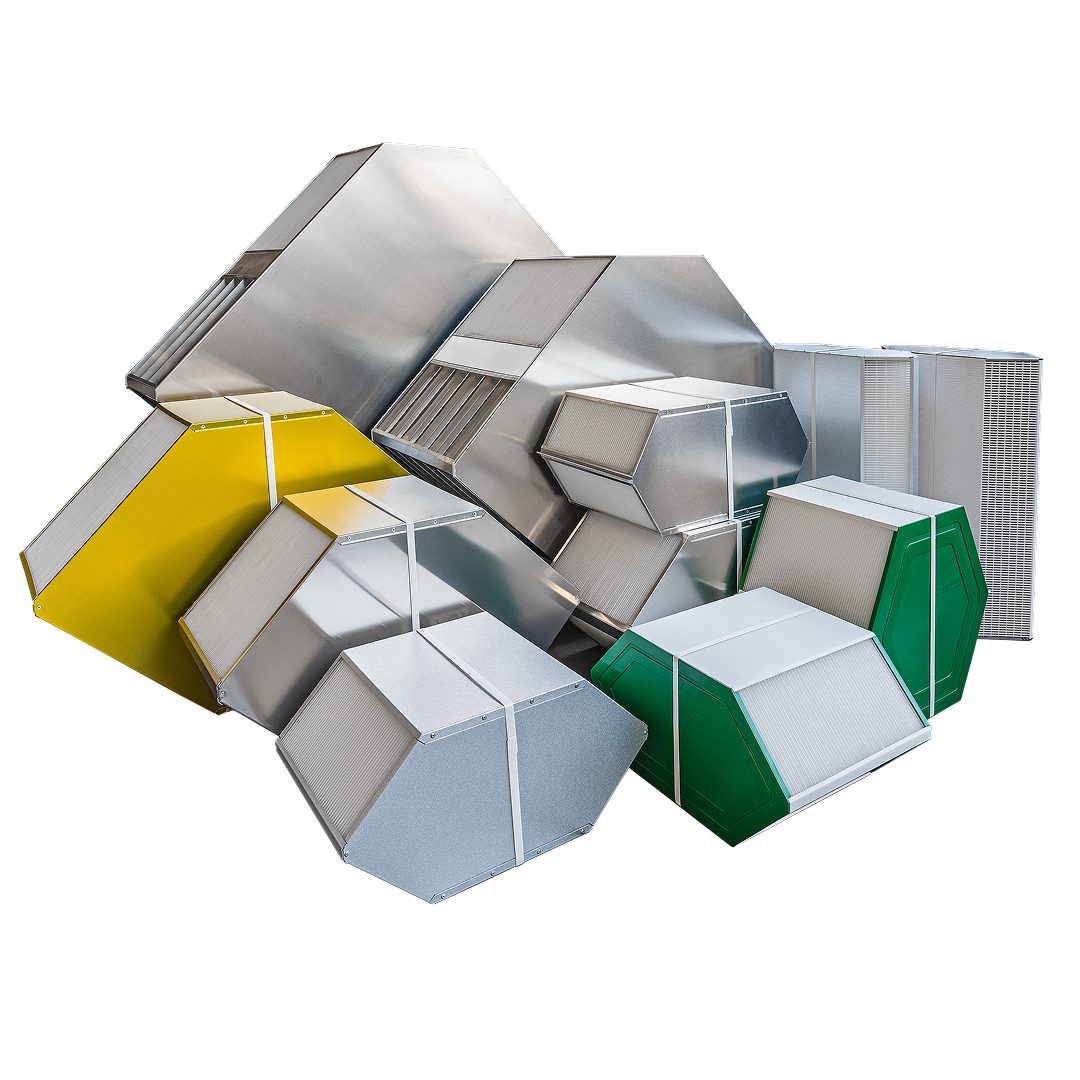

Design and structure

3D model

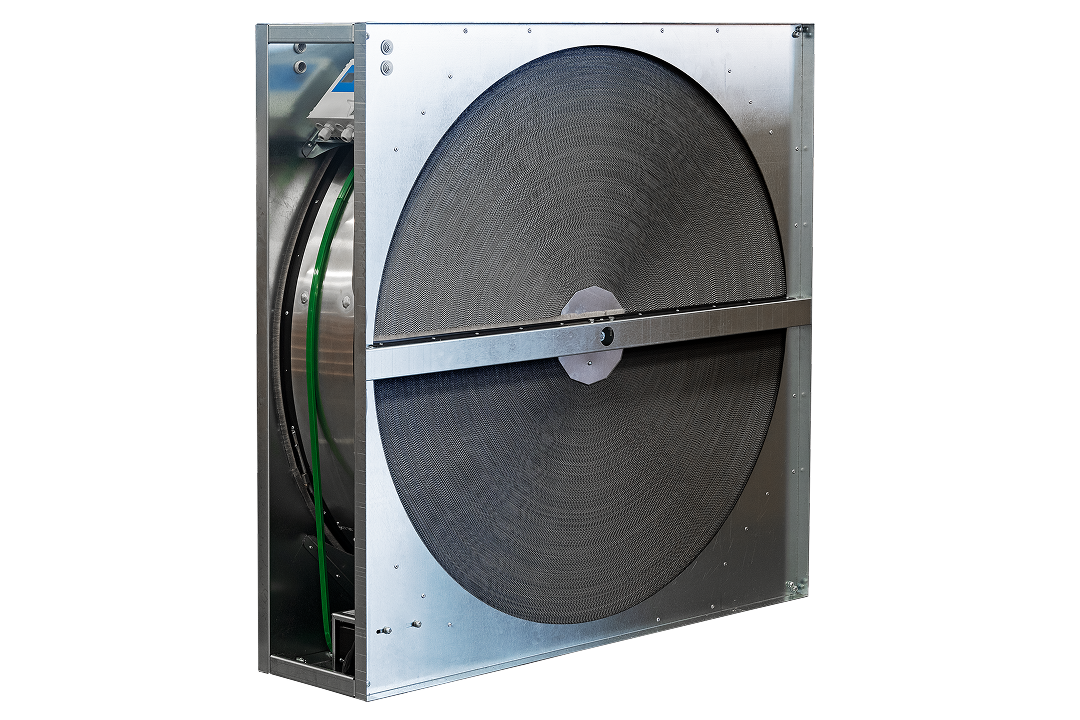

A perforated aluminum wheel rotates between the warmer exhaust air and the cooler supply air. As it turns, the matrix absorbs heat from the exhaust air and releases it back to the supply stream.

In cold weather, warm, moist exhaust can condense on the cooler rotor surface, releasing latent heat that is also transferred. No moisture is moved to the supply side.

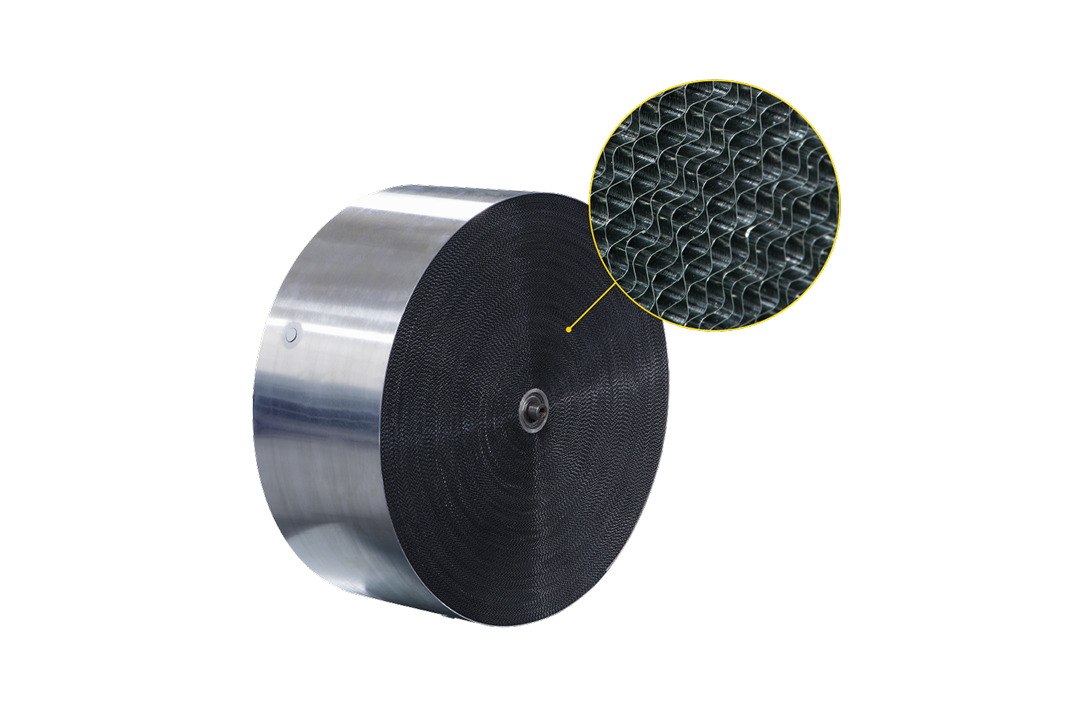

High-grade aluminum foil provides excellent thermal conductivity, light weight, and corrosion resistance.

Options:

- Foil thickness: 0.055 or 0.07 mm

- Wave height (corrugation): 1.4 / 1.6 / 1.8 / 2.1 mm

- Rotor width (depth): 100 or 200 mm

- Galvanized steel — cost-effective for general use.

- Aluminum — lightweight, corrosion-resistant; good for marine/humid sites.

- Stainless steel (AISI 304/316) — for chemically aggressive or highly humid environments.

Most suitable option

Applications

- Residential ventilation — apartments, multi-family houses.

- Commercial buildings — offices, shopping centers, schools, cultural spaces.

- Industrial facilities — workshops, warehouses, production halls.

- Hospitality & wellness — hotels, fitness clubs, swimming pools.

- Large public venues — airports, arenas, exhibition halls, transport hubs.

Decoding Product Specifications

Designation key

R

- R «-»: 200 mm

- RS: 100 mm

x

Rotor type

- «-»: condensing

- «E»: enthalpy

- «N»: sorption

- «K»: epoxy

EX

standard commercial group

Dx

Rotor diameter (mm): 200-2500

x

wave height (mm):

- 1.4

- 1.6

- 1.8

- 2.1

7

foil thickness (mm):

7: 0,07

5.5: 0,055

0

purge section:

0-without.

1-with

1

number of wheel section

A

width (mm): 500-2600

B

height (mm): 500-2600

C

depth (mm): 250-2500