R-E-EX

Technical features

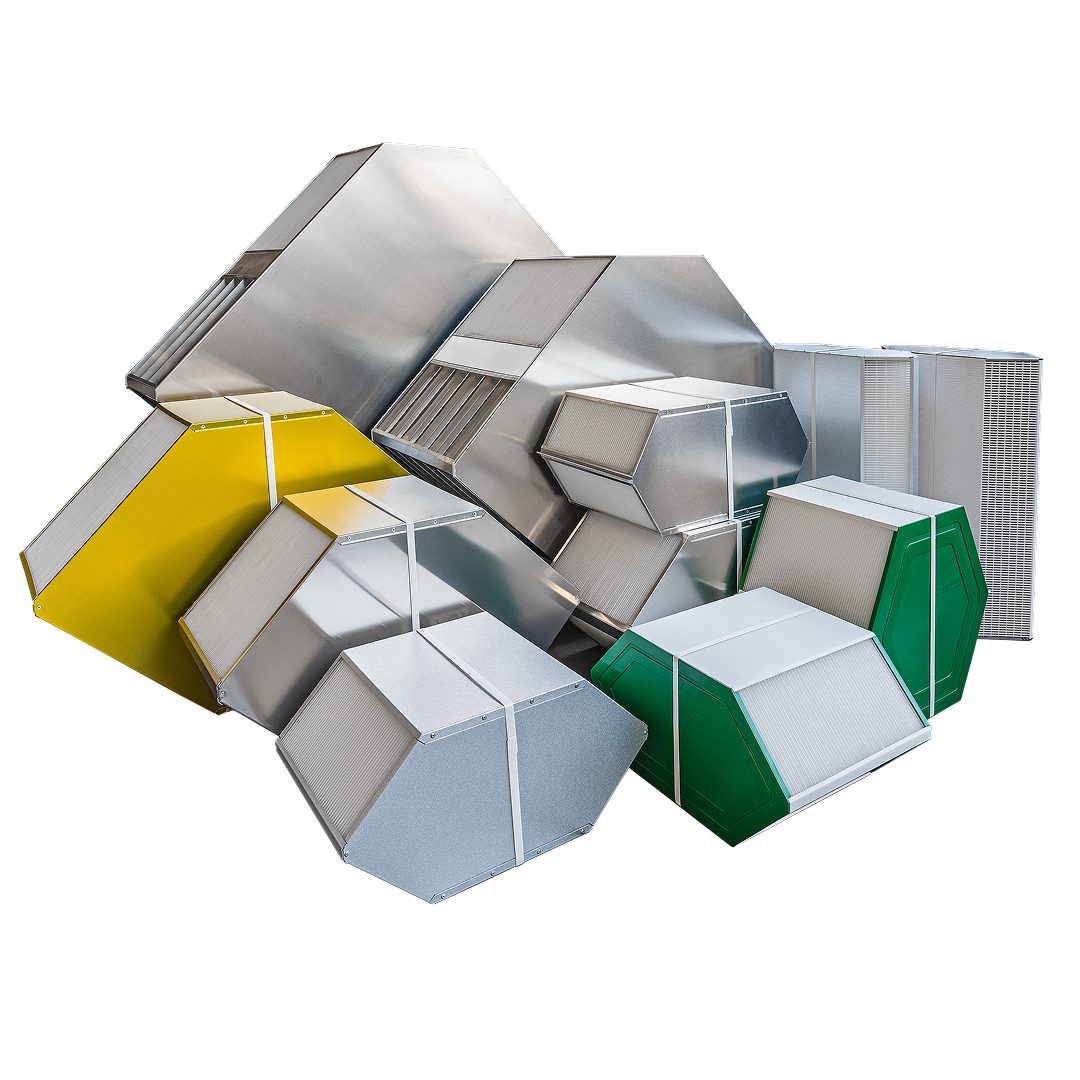

Design and structure

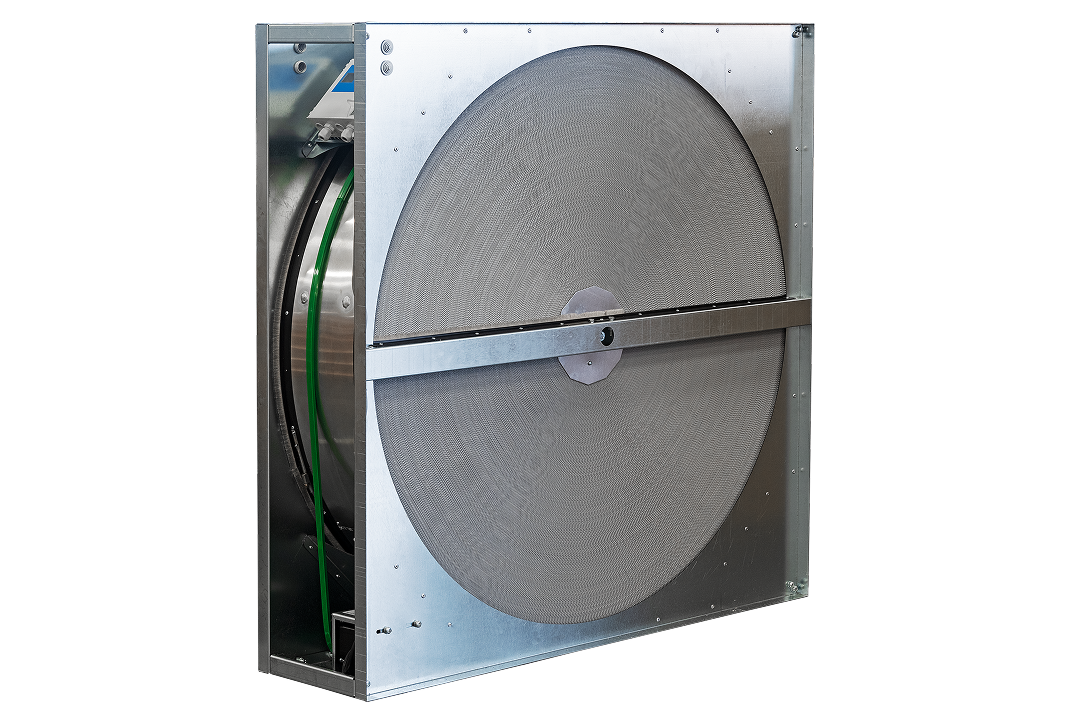

A coated rotor alternately passes through the warm, humid exhaust and the cooler, drier supply stream. It absorbs heat and water vapor from the exhaust, then releases them to the supply air on the next half-turn - without mixing the air streams.

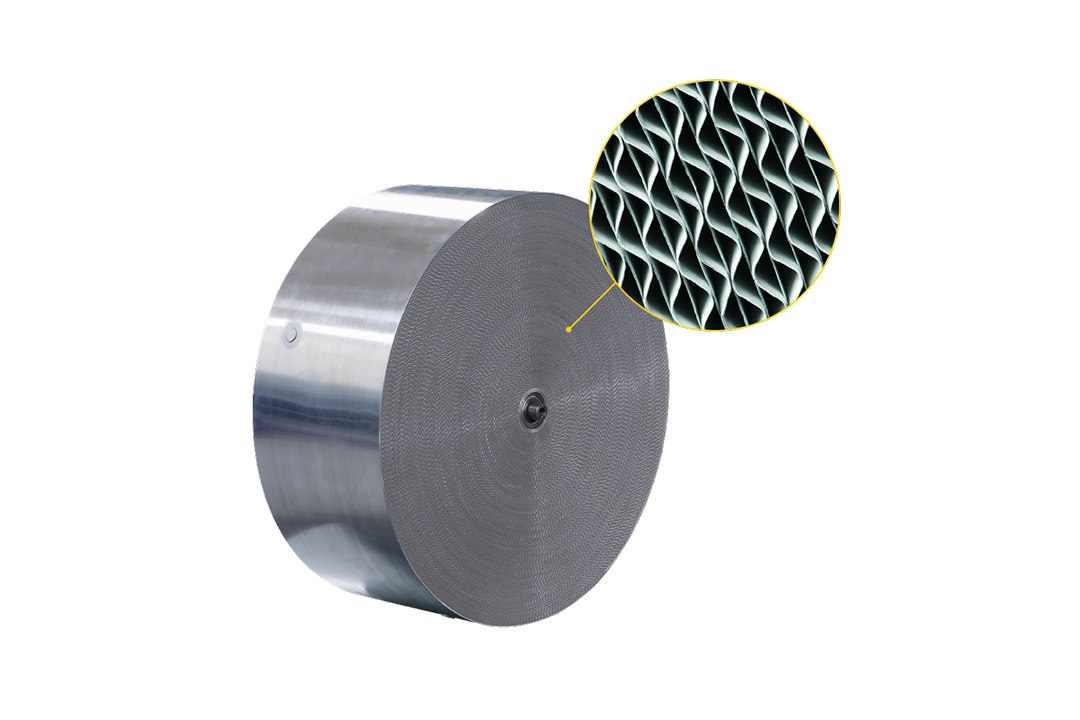

High-quality aluminium foil with a hygroscopic coating for moisture transfer between streams.

Options:

- Foil thickness: 0.055 or 0.07 mm

- Wave height (corrugation): 1.4 / 1.6 / 1.8 / 2.1 mm

- Rotor width (depth): 100 or 200 mm

- Galvanized steel — cost-effective for general use

- Aluminum — lightweight, corrosion-resistant; good for marine/humid sites

- Stainless steel (AISI 304/316) — for chemically aggressive or highly humid environments

Main areas of use

Applications

- Residential ventilation — apartments, multi-family houses.

- Commercial buildings — offices, shopping centres, schools, cultural spaces.

- Industrial facilities — workshops, warehouses, production halls.

- Hospitality & wellness — hotels, fitness clubs, swimming pools (humidity control with enthalpy/sorption rotors).

- Large public venues — airports, arenas, exhibition halls, transport hubs.

Decoding Product Specifications

Designation key

R

- R «-»: 200 mm

- RS: 100 mm

x

Rotor type

- «-»: condensing

- «E»: enthalpy

- «N»: sorption

- «K»: epoxy

EX

standard commercial group

Dx

Rotor diameter (mm): 200-2500

x

wave height (mm):

- 1.4

- 1.6

- 1.8

- 2.1

7

foil thickness (mm):

7: 0,07

5.5: 0,055

0

purge section:

0-without.

1-with

1

number of wheel section

A

width (mm): 500-2600

B

height (mm): 500-2600

C

depth (mm): 250-2500