Articles / 28.05.2025

Polystyrene plate heat exchangers: simple, smart and built to last 💨

Not every ventilation system needs to transfer moisture or rely on complex membranes. Sometimes, simplicity is the smartest choice — especially when you're looking for dry, reliable, and cost-effective heat recovery.

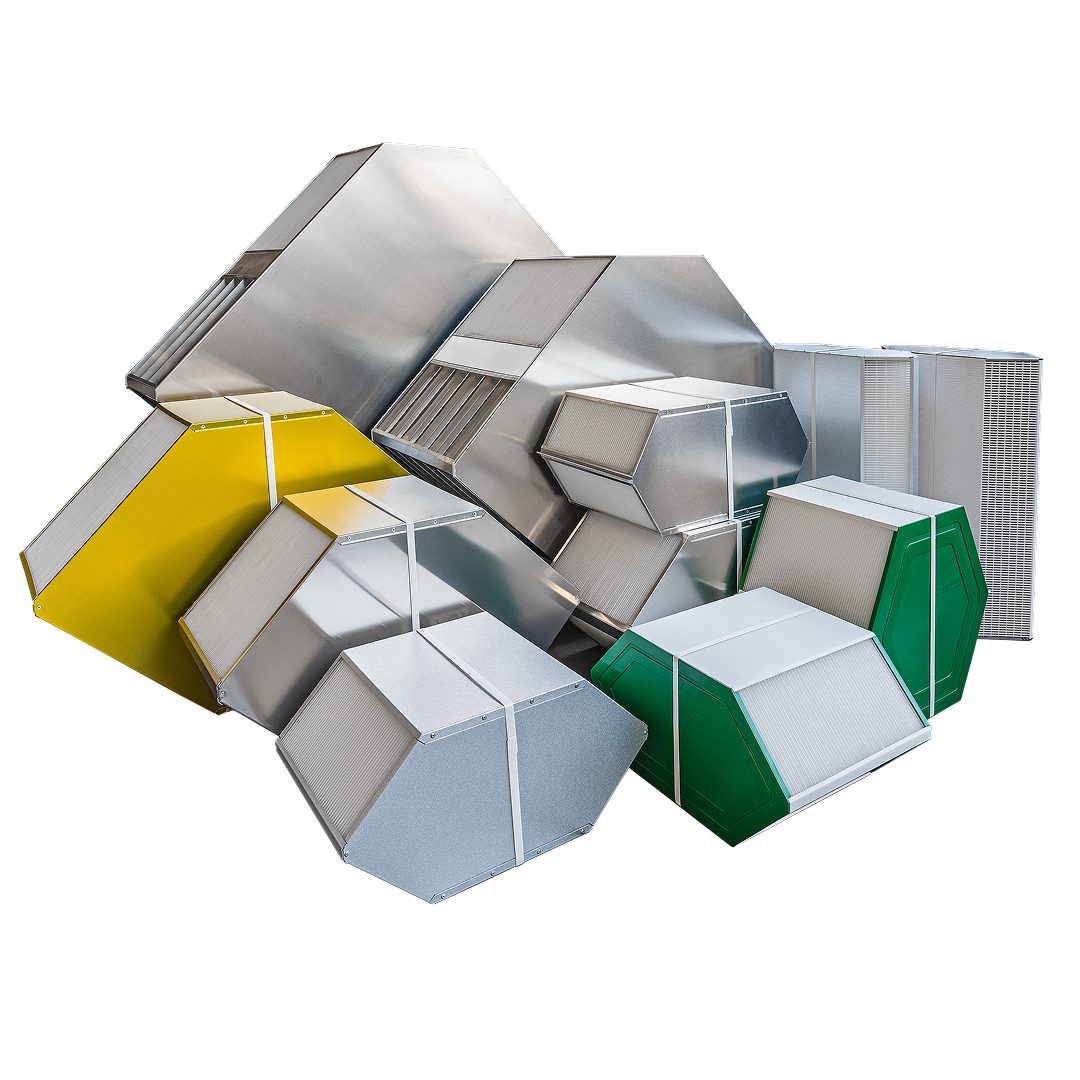

These heat exchangers are built from durable polystyrene plates arranged to separate the supply and exhaust air streams. As air moves through the exchanger, heat transfers across the plastic surfaces — with no contact between airstreams, no moisture exchange, and no risk of contamination. Just clean, efficient recovery of sensible heat (temperature only).

How does it work?

Polystyrene plate heat exchangers operate on the principle of sensible heat conduction. Inside the exchanger, parallel polystyrene plates form alternating channels for supply and exhaust air. These plates act as thermal barriers, allowing heat to transfer from the warmer airflow to the colder one via direct conduction through the solid plastic wall, without any mixing of air or transfer of humidity.

The performance of the system depends on:

- total heat transfer surface area,

- thermal conductivity and thickness of the plates,

- airflow rate and velocity balance.

Thanks to the low thermal resistance of polystyrene and the optimized geometry, ZERN ENGINEERING exchangers achieve heat recovery efficiencies up to 90%, while maintaining full airstream separation — a critical factor for air hygiene and system safety.

Where do they work best?

🏢 Small offices and meeting rooms

🏠 Apartments and private homes

🏫 Schools, kindergartens, libraries

🏪 Retail stores and customer zones

❄️ Any building in a dry or cold climate

Polystyrene heat exchangers are ideal for HRV (heat recovery ventilation) systems where humidity control isn’t required. They’re compact, reliable, and efficient — especially in regions with long heating seasons.

What’s the benefit in real numbers?

Let’s say we install a ZERN ENGINEERING polystyrene unit rated for 400 m³/h, running 12 hours per day all year round.

🌨️ In winter:

- Outside air: –5 °C → Indoor target: +20 °C

- With ~75% heat recovery, that adds up to:

- ~8–10 kWh saved per day

- Over 5 months: ~1,300–1,500 kWh recovered

- ~€260–300 saved on heating

☀️ In summer:

- No moisture transfer, but still benefits from pre-cooling incoming hot air

- Saves ~3–4 kWh/day on AC load

- Over 4 months: ~500–600 kWh

- ~€80–100 in cooling savings

🧾 Total yearly savings per unit: €340–400, with no serviceable parts and zero mechanical wear.

Why ZERN ENGINEERING?

Because we believe great ventilation should be:

💰 Cost-effective in the long run — real energy savings, year after year

🧼 Clean and safe — dry heat transfer without any risk of air mixing

🧩 Easy to install and replace — our units are sized to fit standard ventilation systems

🌍 Resilient — works in any climate, without corrosion or mold risks

Polystyrene plate heat exchangers don’t try to do everything — they focus on one thing and do it well: recovering heat, simply and dependably.

Latest news from ZERN ENGINEERING