Articles / 12.09.2023

Hello, ZERN ENGINEERING community!

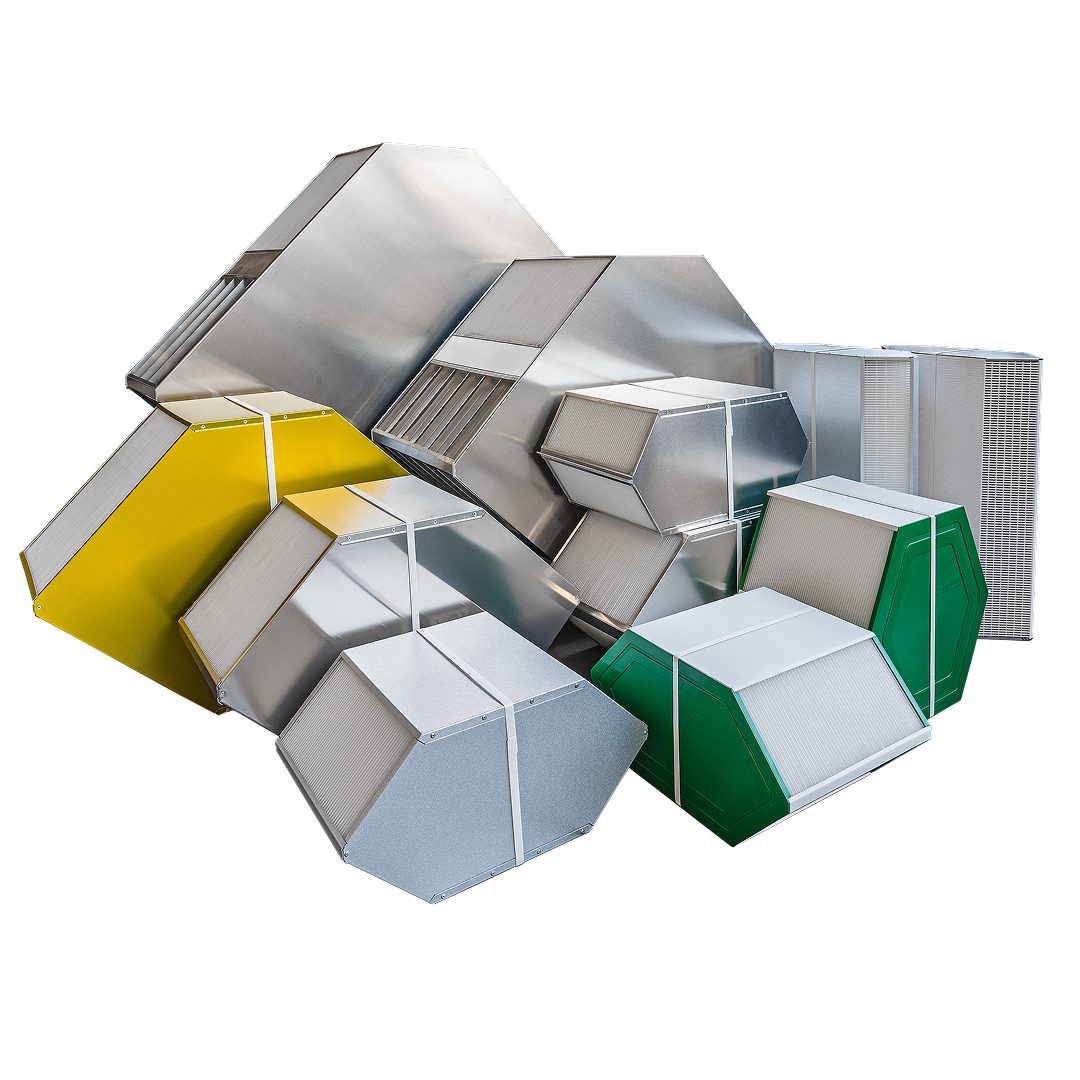

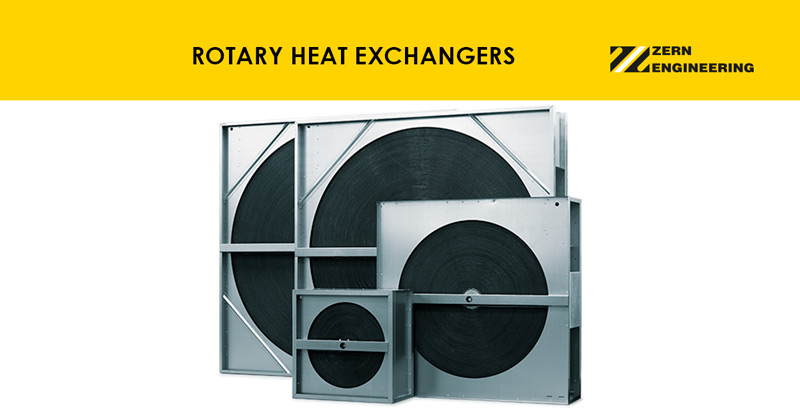

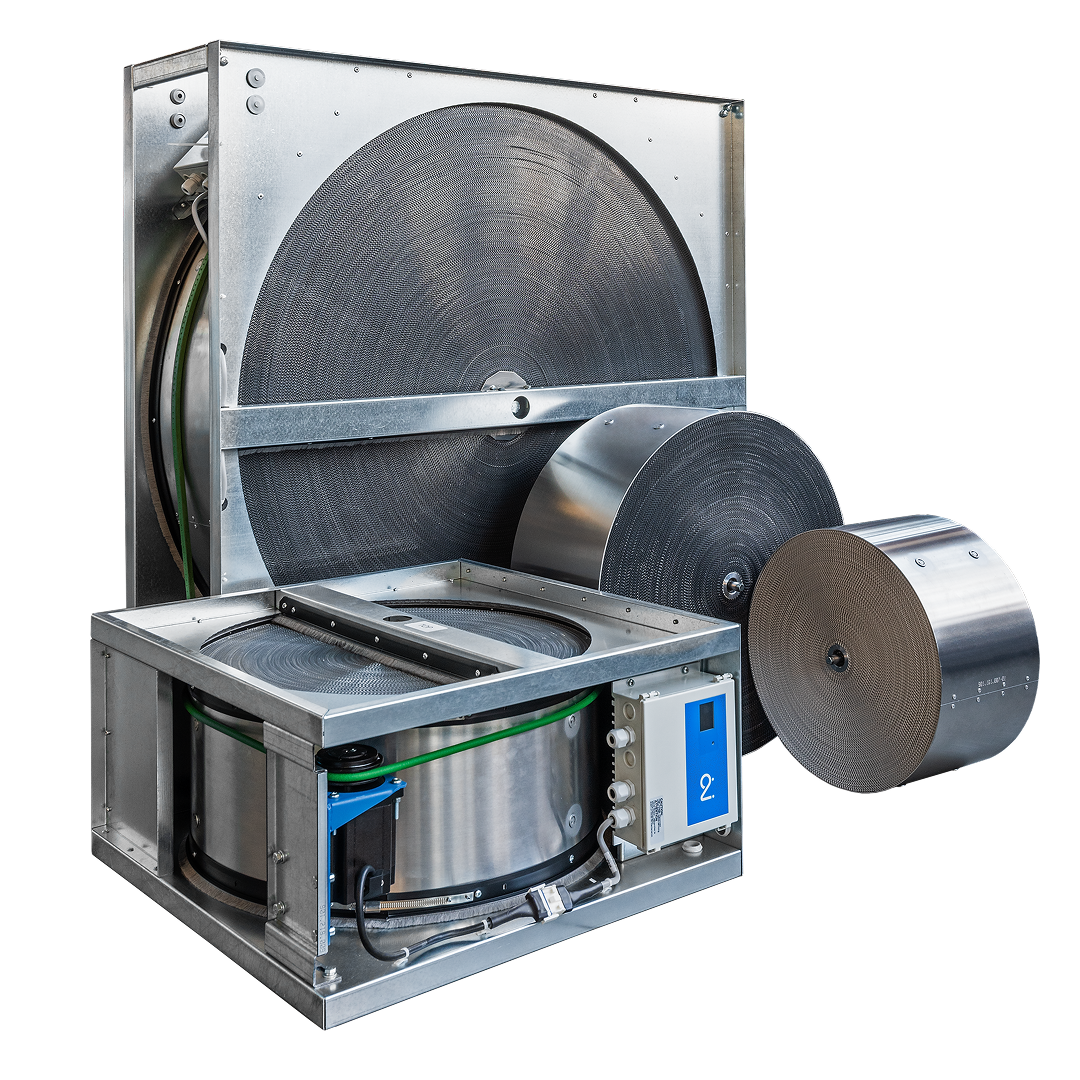

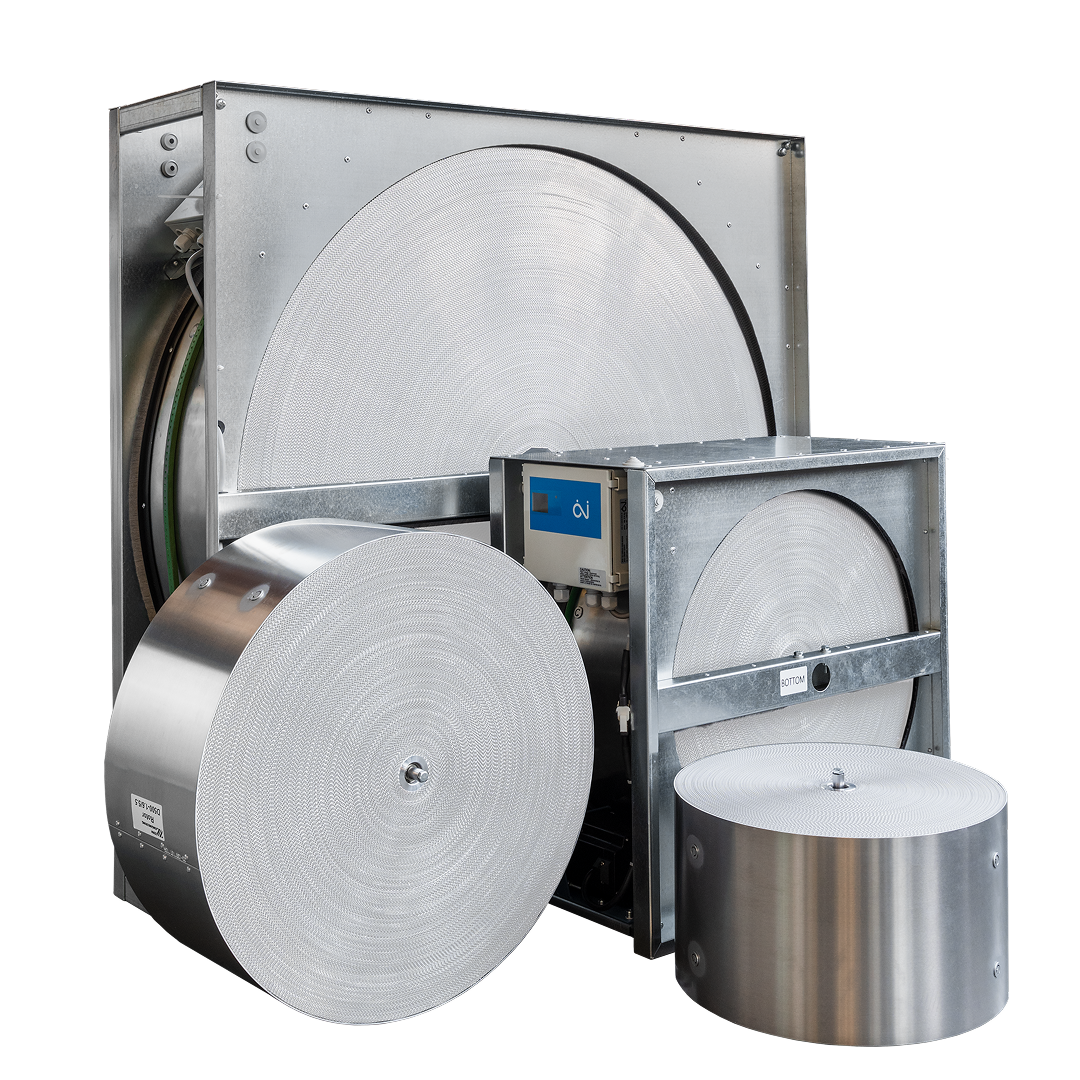

Today we would like to tell you about another area of our production - rotary heat exchangers.

Rotary heat exchangers are a proven heat recovery technology that has been used in many industries and climates and is still being used successfully in various HVAC systems.

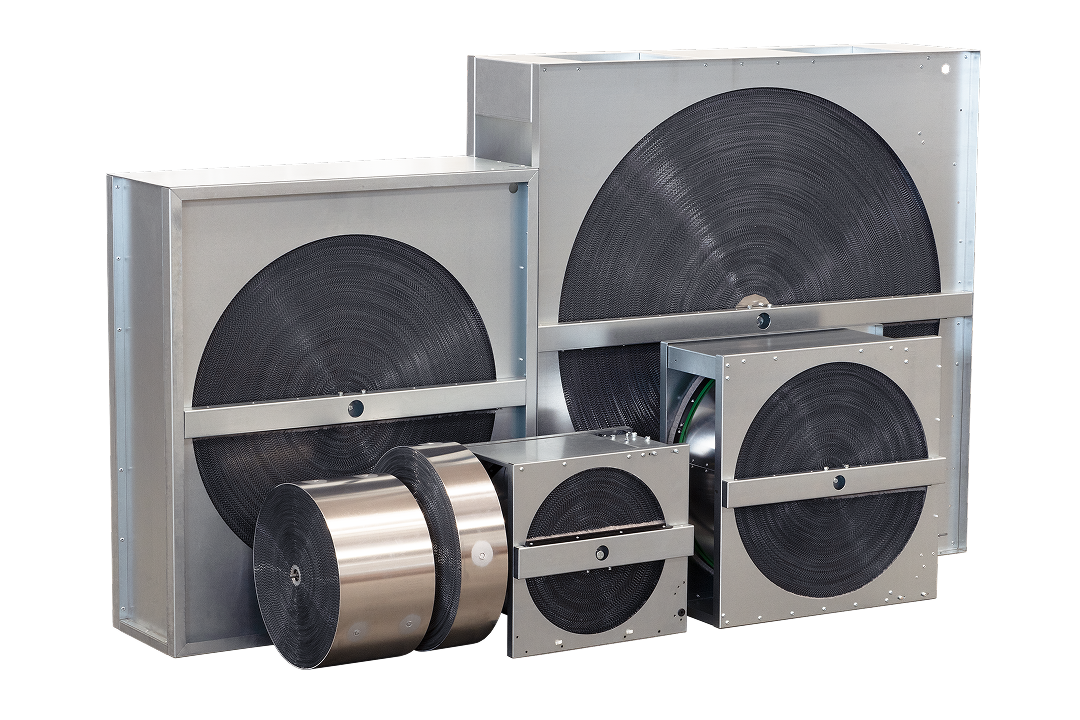

The main operating element of a rotary heat exchanger is its rotor wheel, a heat-intensive matrix. Rotating alternately between the supply and exhaust sections, the wheel is heated by the warmer flow and transfers heat to the cooler flow, thereby heating it.

Benefits:

Energy efficiency: Rotary heat exchangers can dramatically reduce your energy consumption by recycling heat, making your HVAC systems more sustainable and cost-effective.

Improved indoor air quality: Rotary HE helps maintain a healthy indoor environment by ensuring a constant supply of fresh, filtered air, which is essential for your well-being.

Cost savings: Lower energy bills and reduced maintenance costs are just some of the financial benefits you can enjoy.

Ready to experience these advantages firsthand?

Visit our website zern-engineering.com to explore our range of rotary heat exchangers and find the perfect solution for your needs.

Latest news from ZERN ENGINEERING

Explore more articles and updates

Product categories

Types and variations

Condensing rotary heat exchangers

Series:

R-EX

Sensible-only heat recovery for dry ventilation where humidity transfer is not required. It is efficient and easy to integrate.

Enthalpy rotary heat exchanger

Series:

R-E-EX

Hygroscopic coating transfers heat and moisture to help keep indoor RH comfortable in homes, offices, and public spaces.

Sorption rotary heat exchanger

Series:

R-N-EX

Advanced sorptive layer for high moisture recovery and stable indoor climate — well suited for swimming pools, fitness centers, and demanding commercial spaces.

Technical features

Design and structure

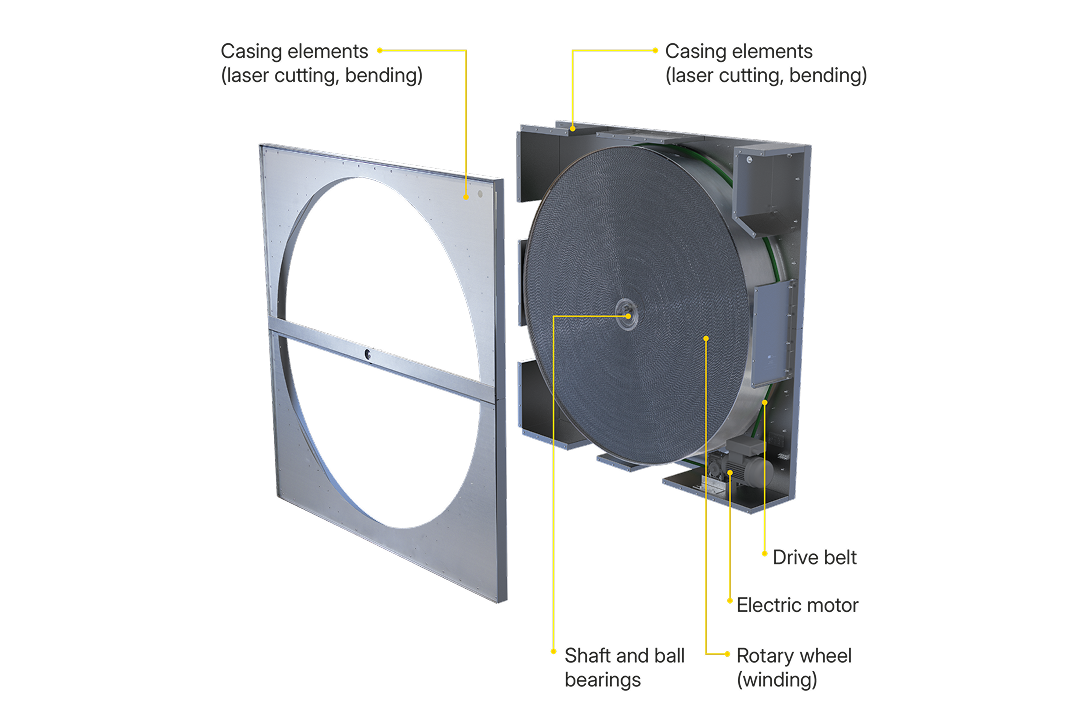

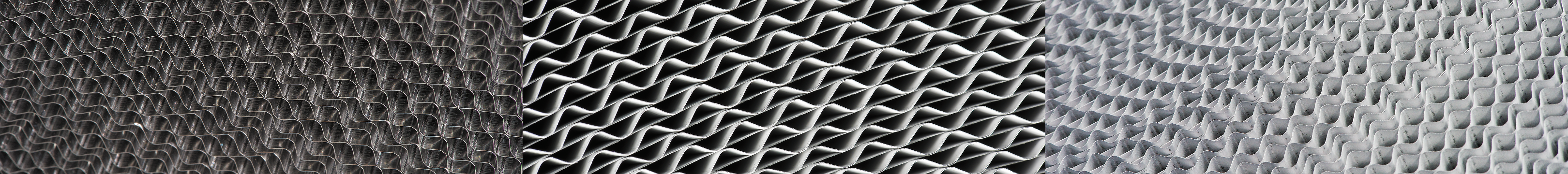

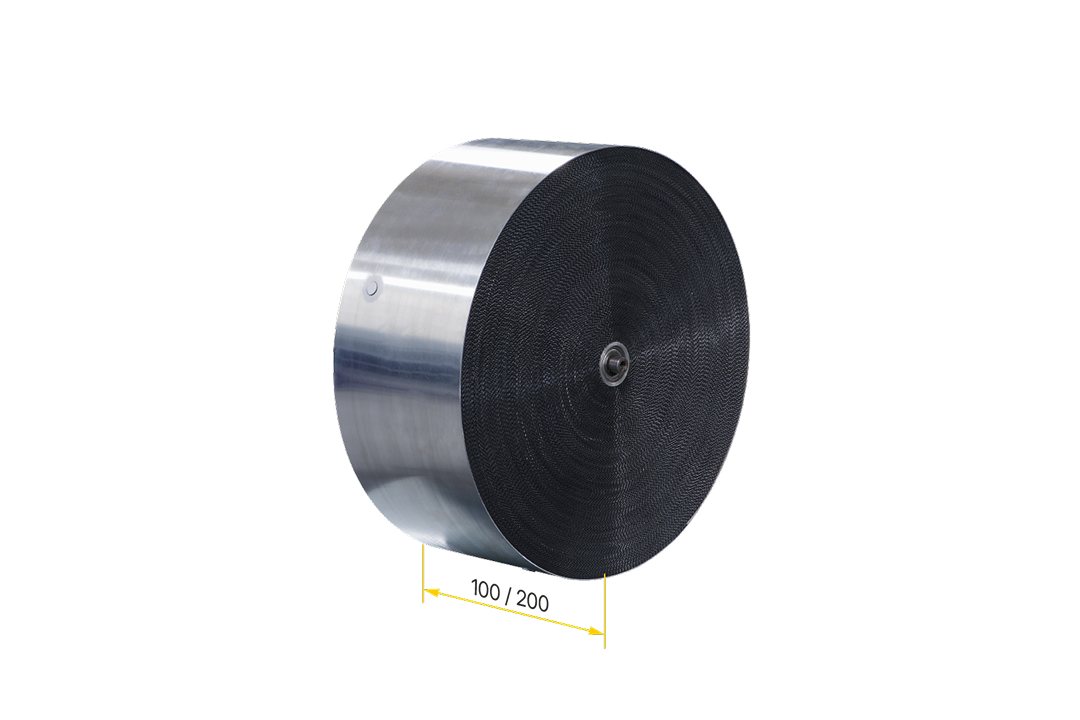

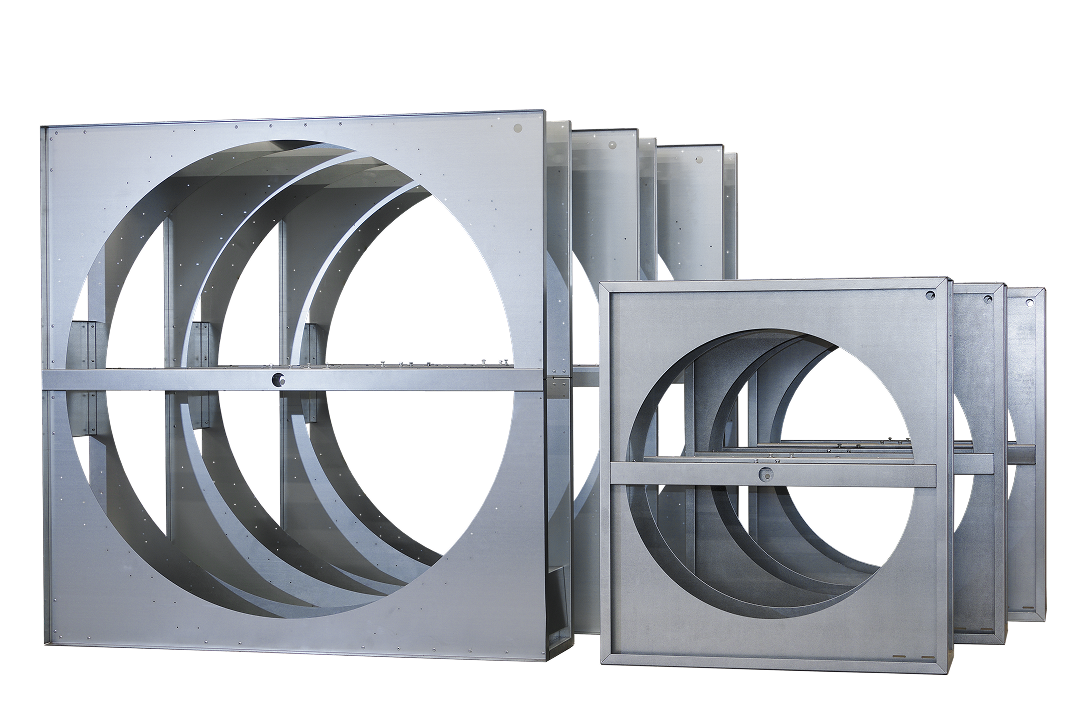

A rotary heat exchanger consists of a rotating wheel made up of numerous small air ducts or channels, typically constructed from aluminum. This wheel rotates between two separate air streams: the warm exhaust air and the cooler incoming fresh air. As the wheel turns, it absorbs heat from the outgoing air and transfers it to the incoming air, effectively recovering energy that would otherwise be lost. In units equipped with hygroscopic coatings, moisture can also be transferred, facilitating humidity control.

- Foil thickness: 0.055 or 0.07 mm

- Wave height (corrugation): 1.4 / 1.6 / 1.8 / 2.1 mm (trade-off between pressure drop and efficiency).

- Rotor width (depth): 100 or 200 mm for compact or high-capacity systems.

- Surface treatments (R-E-EX / R-N-EX): hygroscopic or sorptive coatings (e.g., silica gel / molecular sieve) enable latent-heat and moisture transfer.

- Galvanized steel — cost-effective, durable for standard applications.

- Aluminum — lightweight, corrosion-resistant where weight matters.

- Stainless steel (AISI 304/316) — for harsh, coastal, or chemically aggressive environments.

Modifications

Main components

Rotor (matrix)

Casing

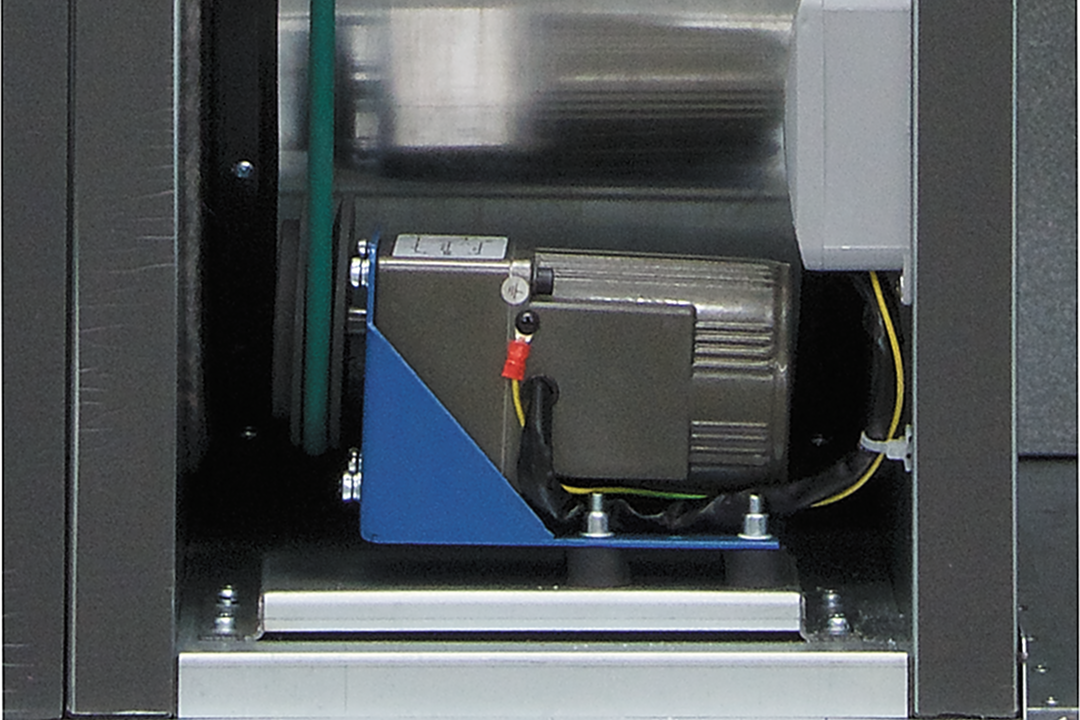

Drive

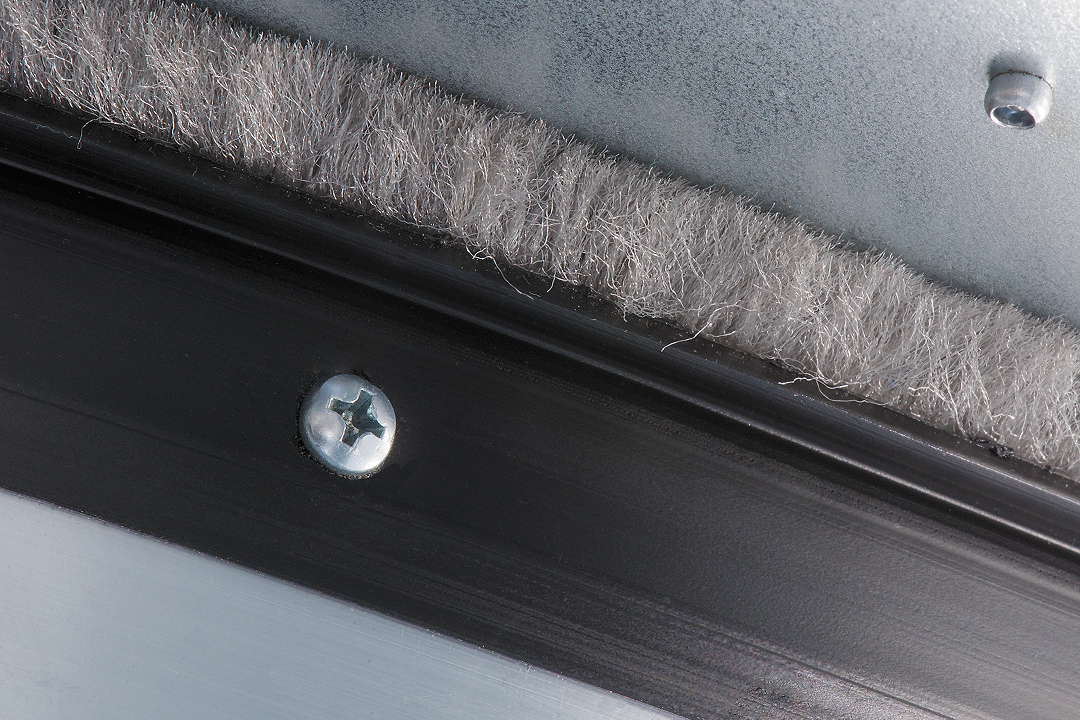

Sealing system

High-quality seals minimize leakage and cross-contamination.

Modifications

Applications

- Residential buildings — apartments, multi-family housing, private homes.

- Commercial facilities — offices, shopping centers, schools, cultural institutions.

- Industrial systems — production halls, warehouses, logistics complexes.

- Hotel and wellness sector — hotels, fitness centers, swimming pools.

- Public spaces — airports, stadiums, exhibition halls, transport hubs.

Product catalog

More information

Discover ZERN ENGINEERING’s full range of heat exchangers. Our product catalog provides detailed specifications, material options, and performance data to help you select the optimal solution for any application