Products / 07.08.2023

Introducing a Range of Enthalpy Plate Heat Exchangers from ZERN ENGINEERING!

Clean and balanced air is the foundation of a healthy lifestyle. Indoor air quality isn't just about cleanliness; it's also about maintaining the correct humidity levels. With increasing legal requirements, building codes, and rising costs, expectations of modern buildings and their heating, air conditioning, and ventilation systems have soared. In this era of increased demands, it is essential to find solutions that meet current and future challenges.

Enthalpy heat exchangers have proven to be a reliable solution to ventilation problems, ensuring a comfortable indoor environment.

Enthalpy heat exchangers are unique in their ability to transfer both heat and moisture without transferring gases and volatile elements from extract to supply air. Their job is to humidify or dehumidify the indoor air according to seasonal needs, such as winter or summer. This is achieved by means of a special polymer membrane that is also resistant to microorganisms.

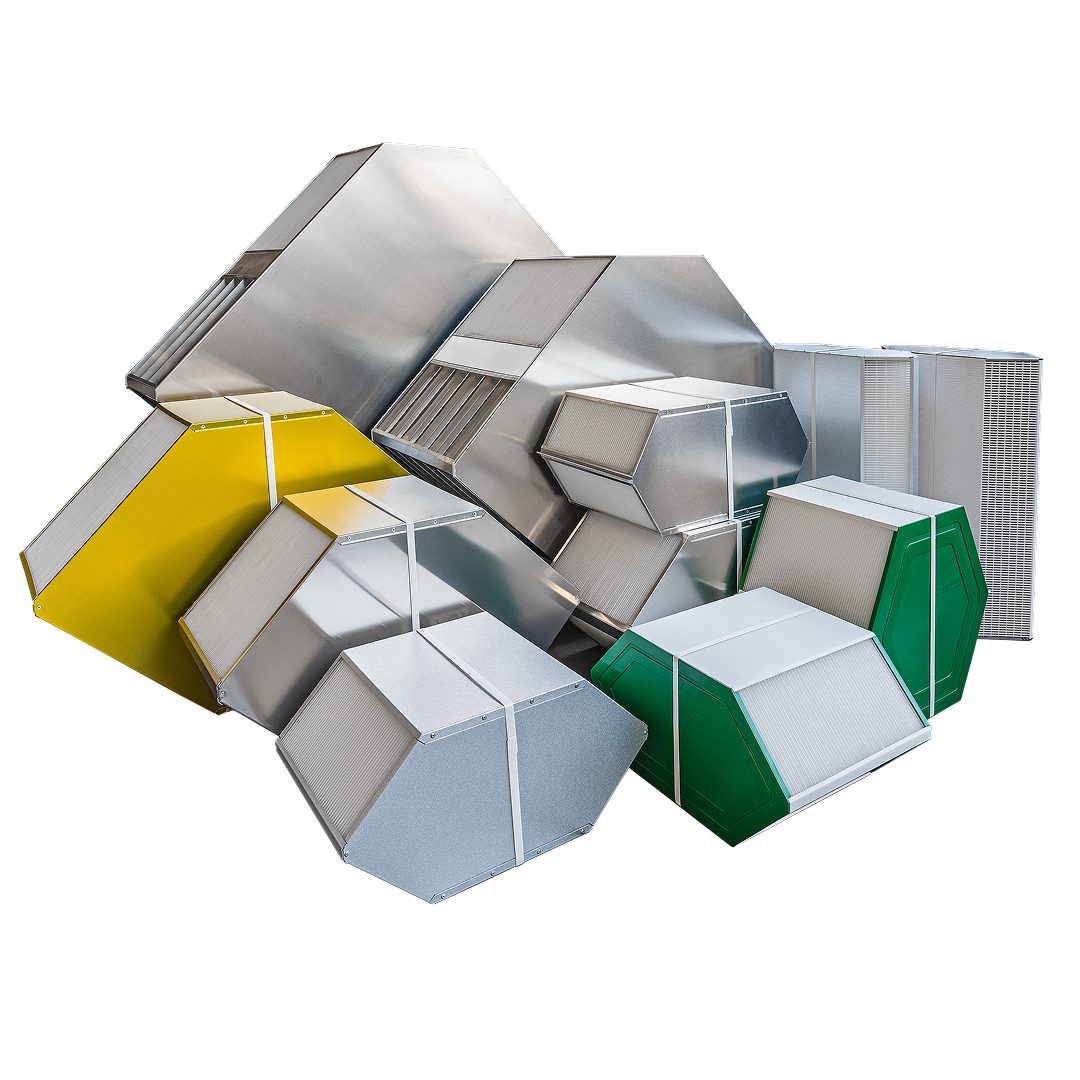

At ZERN ENGINEERING, we offer a wide range of enthalpy heat exchangers to meet different customer needs.

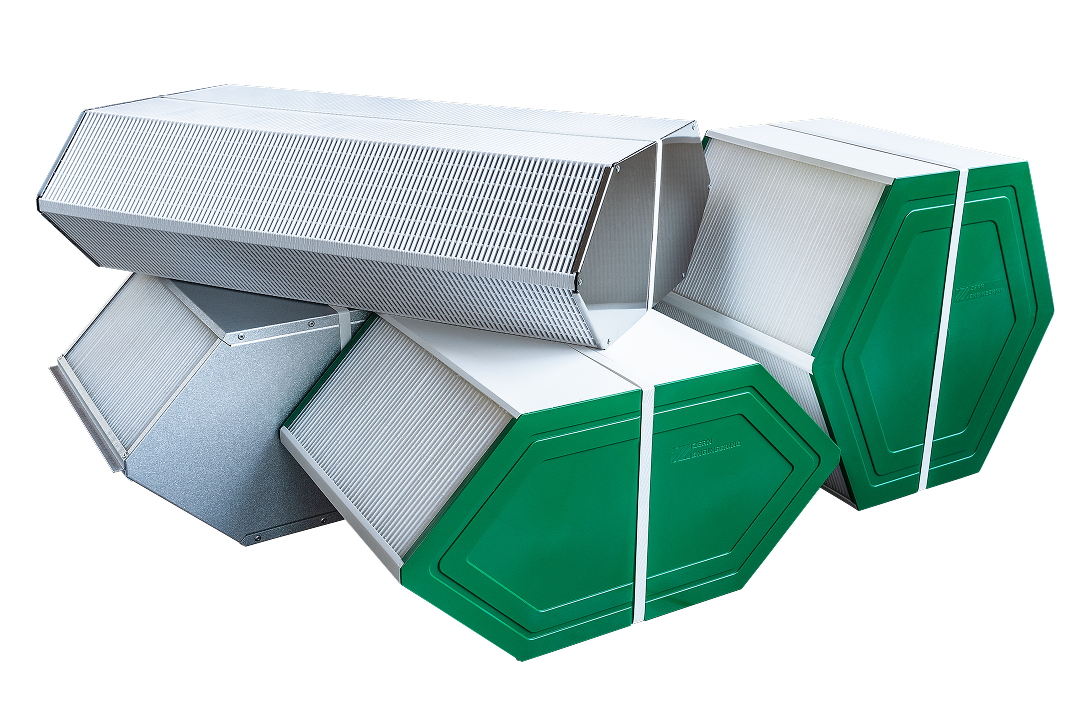

EC Series - a range of counter-flow enthalpy heat exchangers designed specifically for balanced air handling systems. With their high heat recovery coefficient, ability to maintain optimum humidity levels, and efficient air purification, these exchangers have become indispensable in both residential and commercial buildings.

Experience the epitome of indoor comfort and energy efficiency with our Enthalpy Plate Heat Exchangers.

Visit our website zern-engineering to explore our range and improve your indoor air quality today!

Latest news from ZERN ENGINEERING

Explore more articles and updates

Technical features

Design and structure

3D model

- Polystyrene (HIPS) - lightweight, insulated; ideal for compact residential units.

- Aluzinc steel - economical and corrosion-resistant for long-lasting performance.

- Aluminum - lightweight, corrosion-resistant; good for humid sites.

- Epoxy-coated - for chemically active or coastal areas.

- Stainless steel (AISI 304/316) - for aggressive/hygienic sites.

Main areas of use

Applications

- Residential buildings - apartments, multi-family housing, private homes.

- Commercial facilities - offices, shopping centers, schools, cultural institutions.

- Industrial systems - production halls, warehouses, logistics complexes.

- Hotel and wellness sector - hotels, fitness centers, swimming pools.

- Public spaces - airports, stadiums, exhibition halls, transport hubs.

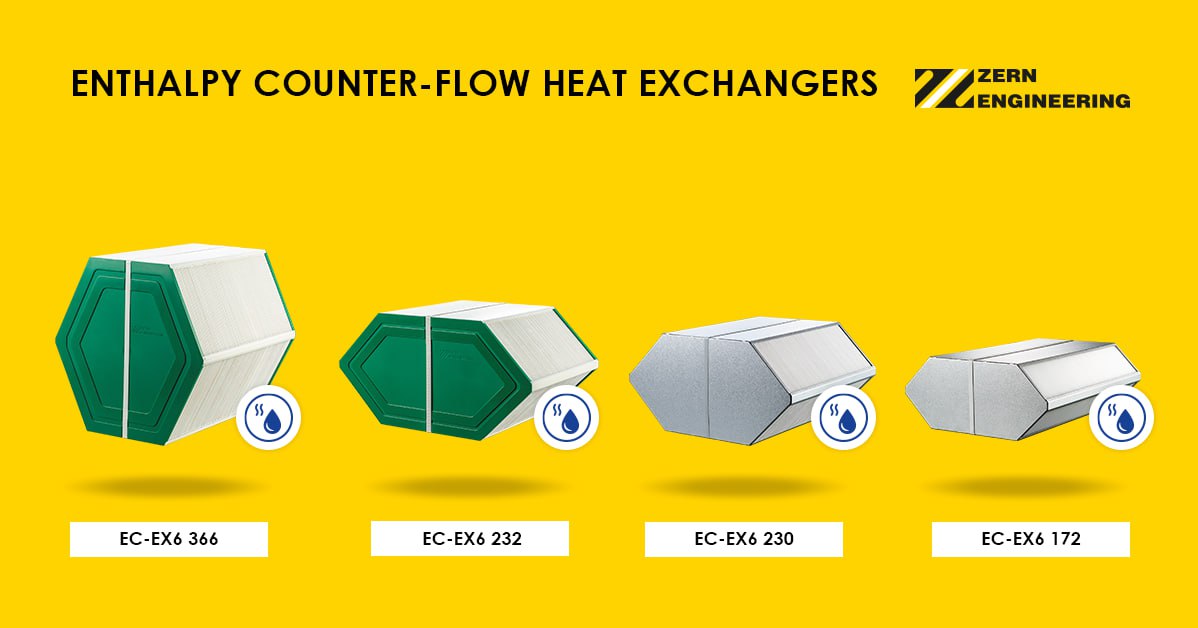

SIZES OF OUR HEAT EXCHANGERS

MODEL LINE

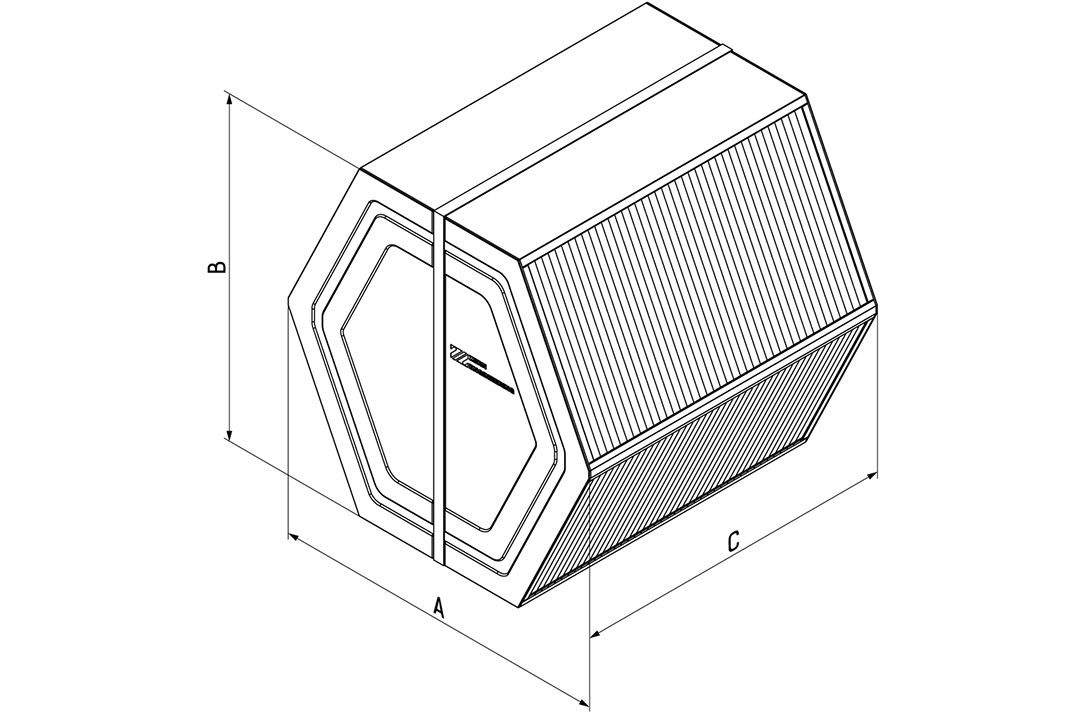

- Dimensions A and B are fixed. Dimension C is the width of the heat exchanger and can be varied.

- Each heat exchanger model can be manufactured with a depth (dimension C) ranging from 100 mm to 600 mm per unit.

- Heat exchangers with a width of 600 mm and above are supplied as two or more units.

| Series commercial group |

Model | A width [mm] |

В height [mm] |

C depth [mm] |

X casing modification |

| ECD / EC-EX6 | 172 | 397 | 172 | 100-600 | 5 / 5.1 |

| 230 | 455 | 230 | 1 / 1.1 / 3 / 3.1 | ||

| 232 | 461 | 232 | 2 / 2.1 | ||

| 366 | 366 | 366 | 2 / 2.1 |

Decoding Product Specifications

Designation key

ECD / EC-EX6

commercial group

B

height (mm)

C

depth (mm)

x

casing modification

- 1 - aluzinc

- 1.1 - aluzinc with a T-profile

- 2 - plastic

- 2.1 - plastic with a T-profile

- 3 - aluminium

- 3.1 - aluminium with a T-profile

- 5 - stainless steel

- 5.1 - stainless steel with a T-profile