Products / 14.08.2023

Diving deeper into cross-flow heat exchangers, we're excited to introduce you to ZERN ENGINEERING's Enthalpy Heat Exchanger Series!

Remembering our earlier discussion of ZERN ENGINEERING's EC Series, we uncover the overall purpose and operating principle of an enthalpy heat exchanger. Refresh your memory or explore the EC Series in detail by clicking here: https://www.linkedin.com/feed/update/urn:li:activity:7094261175940448256/

The E Series Unveiled

E Series - a range of remarkably efficient cross-flow enthalpy heat exchangers meticulously designed for balanced ventilation systems. By incorporating a special polymer membrane, this heat exchanger seamlessly transfers both sensible heat energy and latent water vapor energy, while acting as a formidable barrier against harmful impurities, micro-organisms, dust, and other contaminants.

The above features allow the E series heat exchangers to meet our customers' energy efficiency requirements, while also increasing the comfort and safety of the indoor environment.

Versatile applications

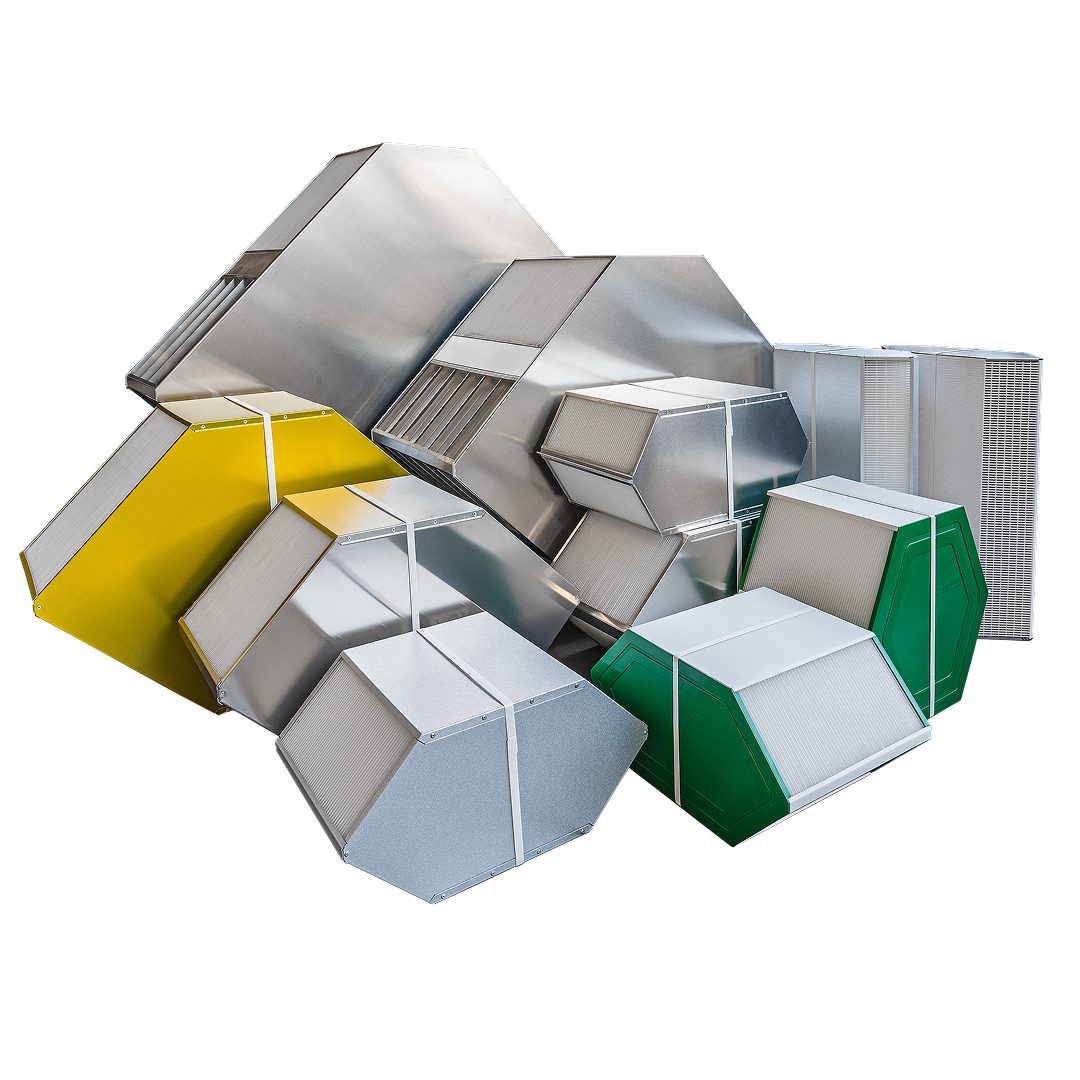

Flexibility is the hallmark of the E series. Whether in monobloc or combi configurations, they address airflow scenarios and ensure optimal performance in different environments.

Tailoring performance to your needs

Notable among its features is the availability of two configurations with different plate spacings - 2.7mm and 4.5mm. This versatility allows our customers to navigate a wide range of airflows while customizing performance parameters to their specifications.

Latest news from ZERN ENGINEERING

Explore more articles and updates

Technical features

Design and structure

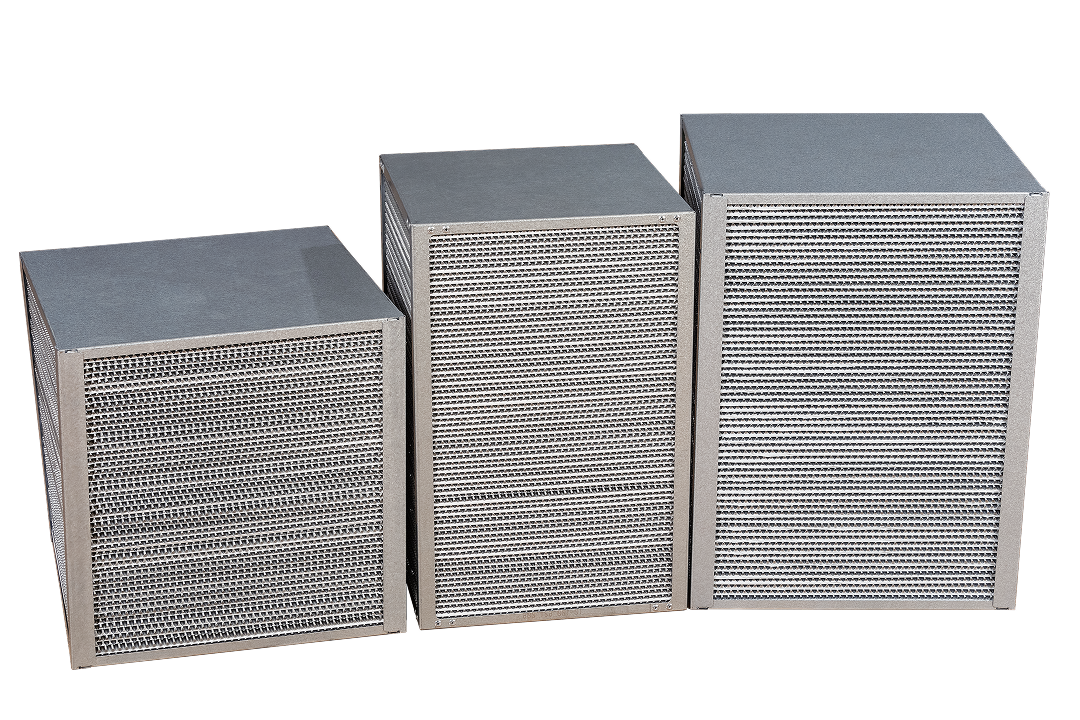

Supply and exhaust air move perpendicularly (90°) through separate membrane-aluminum channels. Heat and water vapor pass through the microporous membrane, while gases, odors, and contaminants are blocked - providing effective recovery and hygienic air separation.

Corrugated aluminum plates laminated with a microporous polymer membrane, which ensures the transfer of sensible and latent heat, moisture diffusion and long service life.

- Aluzinc steel - economical and corrosion-resistant for long-lasting performance.

- Aluminum - lightweight, corrosion-resistant; good for humid sites.

- Stainless steel (AISI 304/316) - for aggressive/hygienic sites.

Main areas of use

Applications

- Residential ventilation - apartments, small homes, single-room ERVs.

- Small commercial - shops, offices, classrooms.

- Hospitality & care (non-sterile) - hotel rooms/corridors, clinics, patient areas.

- Decentralized systems - compact, wall-mounted ERVs and facade units.

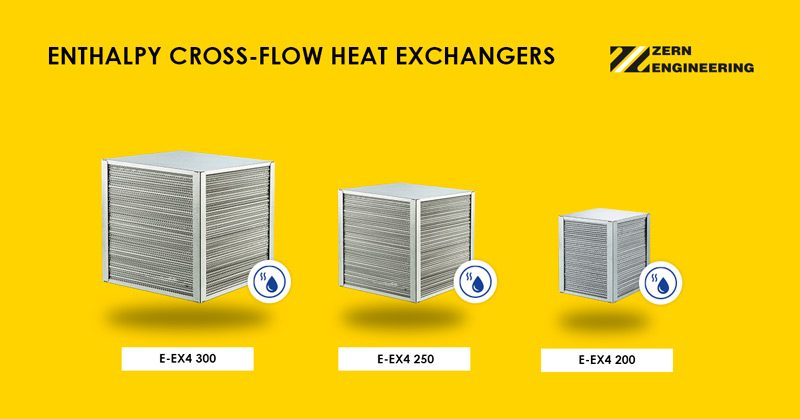

SIZES OF OUR HEAT EXCHANGERS

MODEL LINE

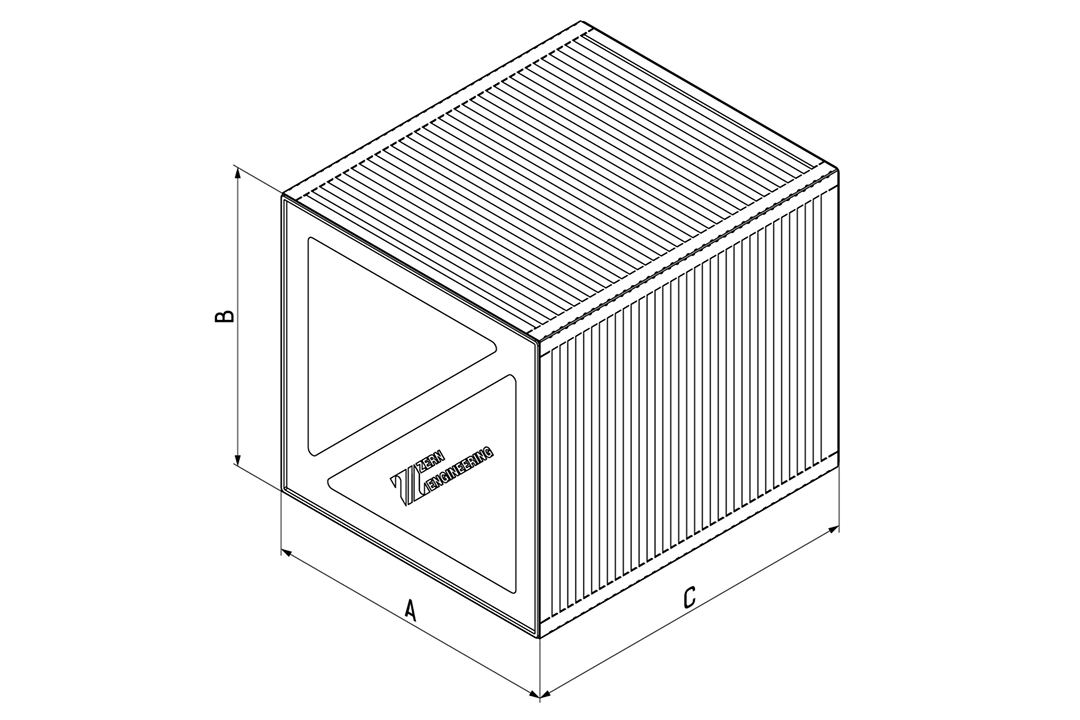

- Dimensions A and B are fixed. Dimension C is the width of the heat exchanger and can be varied.

- Each heat exchanger model can be manufactured with a depth (dimension C) ranging from 100 mm to 800 mm per unit.

- Heat exchangers with a width of 800 mm and above are supplied as two or more units.

| Series commercial group |

Model | A width [mm] |

В height [mm] |

С depth [mm] |

h plate distance [mm] |

X casing modification |

| E-EX4 | 200 | 200 | 200 | 100-400 | 2.7 / 4.5 | 1 |

| 250 | 250 | 250 | 2.7 / 4.5 | 1 | ||

| 300 | 300 | 300 | 2.7 / 4.5 | 1 |

Decoding Product Specifications

Designation key

E-EX4

commercial group

A

width, length (mm)

C

depth (mm)

h

distance between plates (mm)

x

casing modification

- 1 - aluzinc