DESIGN

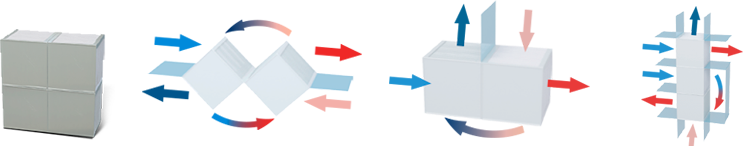

- The heat exchanger has a square shape with the overall dimensions of 200×200 mm, 250×250 mm and 300×300 mm. The heat exchanger depth is from 100 up to 400 mm.

- The heat exchanger consists of a heat accumulating mass (a set of plates) and a casing. The assembled and interconnected plates build a heat

exchanging stack with many air channels. The air channels are crossed at 90° angle. The two air streams moving in the air channels do not get

mixed. - The distance between the plates of 2.4, 2.7 or 3.0 mm provides combination of the maximum efficiency and the lowest pressure differential.

ZERN ENGINEERING™

ZERN ENGINEERING™

sales@zern-engineering.com

sales@zern-engineering.com