DESIGN

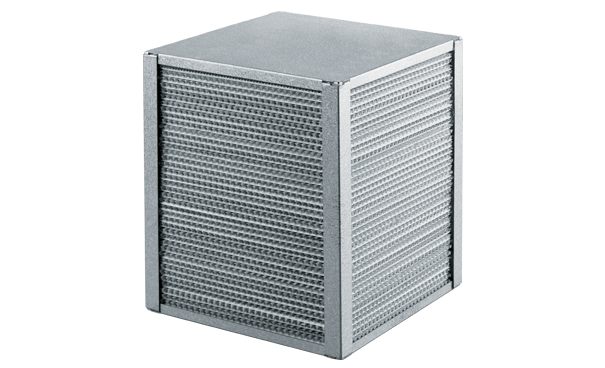

- The heat exchangers are made with the face overall dimensions of 200×200 mm, 250×250 mm, 300×300 mm, 400×400 mm and 500×500 mm. The heat exchanging plates have the depth from 100 mm up to 400 mm.

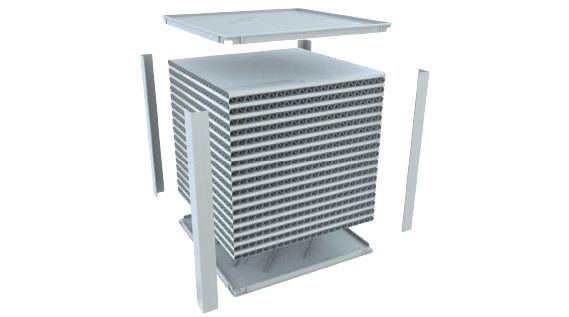

- The accumulating mass consists of aluminium waveform plates, that are laid perpendicular to the channel direction. The wave height is 2.7, 4.5 and 6.0 mm.

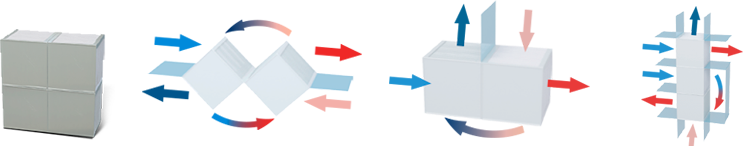

- The vapour-permeable membrane is located between the aluminium plates. This design keeps the two air streams fully separated.

- The casing has no movable parts and is made of various materials.

ZERN ENGINEERING™

ZERN ENGINEERING™

sales@zern-engineering.com

sales@zern-engineering.com